| Numéro |

OCL

Volume 31, 2024

Lipids from aquatic environments / Lipides issus des milieux aquatiques

|

|

|---|---|---|

| Numéro d'article | 21 | |

| Nombre de pages | 13 | |

| Section | Technology | |

| DOI | https://doi.org/10.1051/ocl/2024019 | |

| Publié en ligne | 16 octobre 2024 | |

Research Article

Maximizing key biochemical products of Spirulina platensis: optimal light quantities and best harvesting time☆

Maximisation des principaux produits biochimiques de Spirulina platensis : quantités de lumière optimales et meilleure période de récolte

Department of Chemical Engineering, Faculty of Engineering, Ferdowsi University of Mashhad, Azadi Square, Pardis Campus, 91779-48944, Mashhad, Iran

* Corresponding author: gheshlaghi@um.ac.ir

Received:

15

April

2024

Accepted:

2

September

2024

Light management can optimize algal biomass and biochemical composition, but responses vary based on growth stage and harvesting time. A 22 factorial design along with 3 center point runs was used to investigate the effects of light intensity (50, 100, and 150 μmol photon m−2 s−1) and exposure time (10.5, 16, and 21.5 h) on lipid, protein, carbohydrate, and pigments content, density, and productivity of Spirulina platensis. By analyzing trends in cellular content, the time each key metabolite reached its maximum was chosen as its best harvesting time. Low factor levels during the mid-exponential phase resulted in the highest protein content, while high levels at the very early exponential phase showed the most carbohydrates. Low light intensity favored the accumulation of lipids, chlorophyll, and carotenoids at the end of exponential phase. The highest phycobiliproteins were obtained at intermediate factor levels during the late exponential phase. Harvesting at high levels of factors at the end of exponential phase led to the highest component density. The maximum productivities were observed at high factor levels. These findings emphasize the importance of carefully selecting the harvesting time in different light conditions to achieve the desired biochemical content, density, and productivity in Spirulina applications.

Résumé

La gestion de la lumière peut optimiser la biomasse et la composition biochimique des algues, mais les réponses varient en fonction du stade de croissance et du moment de la récolte. Un plan factoriel 22 et 3 essais au point central ont été utilisés pour étudier les effets de 2 facteurs − l’intensité lumineuse (50, 100 et 150 μmol photon m−2 s−1) et le temps d’exposition (10,5 h, 16 h et 21,5 h)- sur la teneur en lipides, protéines, glucides et pigments, ainsi que sur la densité et la productivité de Spirulina platensis. En analysant les évolutions du contenu cellulaire, le moment où chaque métabolite clé a atteint son maximum a été choisi comme le meilleur moment de récolte. De faibles niveaux de facteurs au cours de la phase exponentielle moyenne ont donné lieu à la teneur en protéines la plus élevée, tandis que des niveaux élevés au tout début de la phase exponentielle ont donné lieu à la teneur la plus élevée en hydrates de carbone. Une faible intensité lumineuse a favorisé l’accumulation de lipides, de chlorophylle et de caroténoïdes à la fin de la phase exponentielle. Les phycobiliprotéines les plus élevées ont été obtenues à des niveaux intermédiaires de facteurs pendant la phase exponentielle tardive. Une récolte à des niveaux élevés de facteurs à la fin de la phase exponentielle a conduit à la densité en composants la plus élevée. Les productivités maximales ont été observées à des niveaux de facteurs élevés. Ces résultats soulignent l’importance de sélectionner soigneusement le moment de la récolte dans différentes conditions d’éclairage pour obtenir le contenu biochimique, la densité et la productivité souhaités dans les applications de la spiruline.

Key words: Spirulina / light intensity / light exposure time / biochemical time trends / harvesting time

Mots clés : Spiruline / intensité lumineuse / temps d’exposition à la lumière / tendances biochimiques temporelles / période de récolte

© A. Maali et al., Published by EDP Sciences, 2024

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Highlights

This study determines the ideal harvesting time and light quantities (intensity and exposure time) for maximizing the content, density, and productivity of carbohydrates, proteins, lipids, and pigments in Spirulina platensis. The findings aim to improve Spirulina biomass for a range of applications.

1 Introduction

Arthrospira platensis, also known as Spirulina, is a photosynthetic, filamentous, prokaryotic, gram-negative cyanobacterium with diverse applications. It is utilized as a dietary supplement in human nutrition (Jara et al., 2018) and as a feed supplement in aquaculture and poultry industries (Altmann and Rosenau, 2022; Ragaza et al., 2020; Raji et al., 2020), because of its high protein content, fatty acids, antioxidants, and vitamins. Moreover, Spirulina exhibits potential in medical and pharmaceutical fields, including the treatment of diabetes (Guldas et al., 2020; Hea et al., 2022), cancer research (Chen et al., 2022), management of viral infections (Tzachor et al., 2021), wound healing (Andrade et al., 2022), vaccine development (Dehghani et al., 2018), and biomarker discovery (Jin et al., 2020). Additionally, Spirulina has demonstrated potential for the biological treatment of wastewater, agricultural, industrial, and pharmaceutical effluents (Mata et al., 2020; Wuang et al., 2016; Wang et al., 2019; Moon et al., 2023), as well as for biofuel production (Haghighi et al., 2022; Rempel et al., 2019) and biofixation of CO2 (Iamtham and Sornchai, 2022; Zhu et al., 2021; Zhang and Liu, 2021; Cui et al., 2019).

The optimization of the biochemical composition and growth characteristics of microalgae (e.g., specific growth rate, culture duration, biomass density, and biomass productivity) are critical steps in meeting the requirements of various applications mentioned above. Thus, understanding the time trends of the key cellular components such as protein, lipid, carbohydrate, and pigments are essential for achieving desired optimization and tailoring microalgal characteristics based on specific applications. The presence of high levels of pigments, particularly phycobiliproteins (PBP) (i.e., phycocyanin (PC), allophycocyanin (APC), and phycoerythrin (PE)), and protein content are considered vital in medical and food sciences, respectively. Additionally, maximizing lipid content enables efficient biodiesel production while emphasizing carbohydrate content is preferable for bioethanol production.

Light irradiance is a crucial factor in algae cultivation, influencing photosynthesis, growth kinetics, biomass productivity, and biochemical composition. Fine-tuning of light conditions, including intensity, photoperiod, and spectrum, is essential for achieving desired optimization by regulating algal metabolism (Glemser et al., 2016; Li et al., 2021; Vonshak, 1997; Niangoran et al., 2019).

Increasing light intensity (I) up to saturation levels at any wavelength enhances biomass yield, irrespective of the harvest time (Niangoran et al., 2021; Chofamb, 2021; Chen et al., 2010; Vonshak and Tomaselli, 2000). Regarding PBP content, it has been observed that lower light intensities increased PC content when all the cultures were harvested on day 11, so that some cultures were in the exponential and others in stationary phases of growth (Chofamb, 2021). Furthermore, the time trends of APC content (Dejsungkranont et al., 2017) and PC content (Xie et al., 2015; Chen et al., 2013; Dejsungkranont et al., 2017) under different light intensities showed that lower light intensity resulted in higher contents late at the exponential phase. On the contrary, one study showed that higher light intensities favored PC content when the measurements were performed from the samples taken on day 8 during the exponential phase (Niangoran et al., 2021).

Extending the light exposure time (T) at a constant intensity enhances biomass yield, regardless of the harvest time (Niangoran et al., 2021; Prates et al., 2018). The effect of light exposure time on PC content has been inconclusive. For instance, exposure to 24 h of light increased PC content compared to partial light exposure, when all the samples were taken on day 8 during the exponential phase (Niangoran et al., 2021). However, in another study, partial irradiation favored PC content when the experiments were carried out for a longer period of time—10 days—until the early stationary phase (Prates et al., 2018).

Spirulina cultivation under different light spectra (i.e., white, blue, and red) showed the highest biomass concentration in red and the lowest in blue light, as well as higher lipid content in red and white lights compared with blue over a 20-day period. At this time, cultures under red and white illumination reached the death phase, while the culture under blue light was in the middle of exponential phase (Vo et al., 2017). The above results were confirmed when the effect of four LED light colors (red, white, yellow, and blue) was studied on biomass density (Niangoran et al., 2018). However, in some studies, white light resulted in higher biomass density than red light when the experiments were continued to the stationary phase (Prates et al., 2018; Solis.Méndez et al., 2020). Furthermore, it was observed that using a combination of lights with different wavelengths can increase Spirulina platensis biomass density compared with applying a single spectrum (Prates et al., 2018; Si et al., 2016). The effect of light spectrum on phycocyanin content is also controversial. For instance, maximum PC content was obtained in cultures illuminated with green spectrum (Prates et al., 2018), while in another study white LED was beneficial for the highest PC content and productivity (Ho et al., 2018).

Studies investigating the impact of different light conditions on Spirulina growth commonly adopt a fixed cultivation time for all measurements, including growth characteristics and cellular biochemical contents. Although this approach seems feasible for measuring biomass density and productivity, it can lead to inconsistent results for certain cellular biochemicals. The time course of some cellular biochemical compounds has an extremum, which is usually shifted with respect to time by applying different conditions. Therefore, it is not logical to harvest the cultures under different conditions on the same day. Instead, all cultivations should be continued at least until the extremum is observed. This study aimed to (a) monitor the growth and the contents of the key cellular biochemicals (i.e., protein, lipid, carbohydrate, and pigments) of Spirulina platensis until the end of exponential phase under various light conditions. (b) determine the maximum values of content, density, and productivity for biomass and the biochemicals and the corresponding times under different experimental conditions. (c) investigate the effects of light intensity, light exposure time, and their interaction using a two-level factorial design with 3 replications in the center point to assess the best conditions for biomass, each key biochemical content, density, and productivity, as well as energy efficiency. Overall, this study enhances understanding of Spirulina cultivation and biochemistry, offering valuable insights for future research. The findings possess the potential to optimize Spirulina cultivation and aid in selecting the optimal harvesting time for various applications.

2 Materials and methods

2.1 Microorganism and cultivation conditions

Spirulina platensis abdf2224 was purchased from Algae Bioresource Development Company of Shiraz-Iran. The autoclaved Zarrouk medium (Zarrouk, 1966) was used for Spirulina culture with an initial pH of 9.0. The inoculum was grown in a 250 mL Erlenmeyer flask for seven days at 30 ± 1 °C under a 16:8 light/dark cycle with the light intensity of 90 μmol photon m−2 s−1, which corresponds to the photosynthetic photon flux density (PPFD), and sparged with a sterile air at a flow rate of 0.5 vvm. The experiments were performed in a 1‑liter working volume photobioreactor illuminated by cool white (5500K) LEDs (400–700 nm, 2.8–3.4 V, EPILED, Taiwan) with adjustable light intensity and light exposure time features. The aeration and temperature conditions were the same as mentioned above. The initial biomass density in all experiments was set to 0.059 ± 0.003 gCDW L−1, and the evaporated water was compensated by adding sterile distilled water daily before sampling. Sampling was performed daily just before the dark time. The culture was harvested when the optical density at 680 nm (OD680nm) reached 2.5, which was close to the end of exponential phase in each experiment. It should be noted that each experiment has a unique calibration curve (not shown), resulting in different final biomass concentrations at OD680 = 2.5.

The individual and synergistic effects of two factors, i.e., light intensity (I) and light exposure time in 24 h (T), on the maximum content (g gCDW −1), density (g L−1), and productivity (g L−1 d−1) of key biochemical components (carbohydrate, protein, lipid, and pigments) were investigated by 22 full factorial design. Four factorial points (± 1 from the center point) and 3 replicates at the center point (CP1, CP2, and CP3), for estimation of pure error and detecting curvature in responses, were used in this design. The levels of each factor are presented in Table 1. For simplicity, the factorial points are represented by a two-letter word, with the first letter indicating the level of light intensity and the second letter indicating the level of light exposure time. For instance, HL represented the experiment with high light intensity and low light exposure time.

The levels of factors for the experimental design.

2.2 Measurement of Spirulina growth and energy efficiency

The Spirulina platensis biomass density in the culture medium was monitored daily by measuring the OD680nm using a UNICO UV-2100 spectrophotometer. The standard growth curve was obtained from the correlation between OD680nm and dry weight biomass (Manirafasha et al., 2018; Ho et al., 2018). The biomass productivity (Px, gCDW L−1 d−1) was calculated using the equation PX = (Xt − X0)/(t − t0), where Xt and X0 are the biomass density (gCDW L−1) at time t (d) and initial time t0 (d), respectively. The maximum specific growth rate (μmax, d−1) was calculated using the equation μmax = (lnX2 − lnX1)/ Δt, where X1 and X2 are the biomass densities (gCDW L−1) at the beginning and end of the exponential phase, respectively, and Ät (d) is the time duration of the exponential phase. The energy efficiency (η, g d−1 kWh−1) of electrical energy to biomass production was calculated using the equation η = (Xf − X0) V/ (tf ELED), where Xf represents the biomass density on the final day of cultivation, V (L) is the volume of culture, and ELED (kWh) is the electrical energy consumed by LEDs during the cultivation time tf (d) (Niangoran et al., 2021).

2.3 Biomass composition characterization

The sampling for evaluation of biomass contents during Spirulina growth was carried out every day for each experiment. The carbohydrate content was measured via the colorimetric phenol–sulfuric method using a glucose calibration curve (Dubois et al., 1956). The protein content was determined via the Lowry colorimetric method with hot sodium hydroxide pretreatment using bovine serum albumin as a standard curve (Lowry et al., 1951). The lipid concentration was estimated by the colorimetric sulfo-phospho-vanillin assay using commercial canola oil as a standard curve (Mishra et al., 2014). For measuring chlorophyll-a (Chl-a) and carotenoid (Cart) concentrations, 3 mL of culture was centrifuged for 10 min at 4200 rpm, and the supernatant was discarded. Then, 3 mL of absolute methanol was added and placed in a water bath at 70 °C for 20 min, followed by centrifugation at 4200 rpm for 10 min. The concentrations were determined by measuring the OD of the supernatant at 470, 653, and 666 nm using Wellburn’s equations (Wellburn, 1994). For determination of phycobiliprotein content, the biomass was recovered from the liquid medium by centrifugation for 10 min at 4200 rpm. The biomass was then suspended in 3 mL of 0.1 M sodium phosphate buffer (pH 7). The suspension was repeatedly frozen at −18°C and thawed at room temperature 12 times. Then, the suspension was centrifuged at 4200 rpm for 10 min. The PBP (PC, APC, and PE) concentrations were determined by measuring the OD of the supernatant at 562, 615, and 652 nm using Bennett and Bogard’s equations (Bennett and Bogard, 1973).

2.4 Statistical analysis

All analysis was performed in three replicates, and the results were expressed as the mean ± margin of error (a = 0.05). The significant difference between means of data was analyzed using analysis of variance (ANOVA), followed by Tukey’s test at a 95% confidence interval. Also, the ANOVA technique evaluated the significant factors (main and interaction) of the model.

3 Results

3.1 Growth characteristics and energy efficiencies

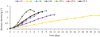

In Figure 1, the growth curve of all cultures is depicted, demonstrating a short time lag phase during the initial stages. While the growth profiles were similar during the first day of the experiments, the HH experiment exhibited more significant cell growth and rapidly entered the death phase. In contrast, the other cultures displayed more extended exponential phases. The LL experiment demonstrated the slowest growth rate, with its exponential phase lasting approximately 20 days.

Table 2 summarizes the growth characteristics obtained from the growth curve and the energy efficiency of each culture. High levels of light intensity and light exposure time promote growth characteristics such as maximum specific growth rate, final biomass productivity, and density. Conversely, low values of these factors resulted in longer culture time, most likely due to a decrease in photosynthetic rate. The culture time for high light exposure time was approximately half of that for the low level, resulting in approximately twice the final biomass productivity and maximum specific growth rate. The effect of light intensity on reducing the culture time was found to be more significant than the effect of light exposure time, according to the ANOVA table (not shown). Moreover, both main effects (I and T) and their interaction positively affected the final biomass density and productivity.

The highest and lowest energy efficiency related to LED for biomass production are in the HH and LL experiments, with values of 2.045 and 0.541 gCDW d−1 kWh−1, respectively. While the energy consumption of LED lighting for high light intensity production surpasses that of low light intensity, the shorter culture time for HH compared to LL (5 versus 20 days) resulted in HH being four times more energy efficient than LL. Based on the ANOVA table (not shown), both light intensity and exposure time have positive effects on energy efficiency.

|

Fig. 1 The cell growth curve of Spirulina platensis under different light conditions. |

Growth characteristics and energy efficiencies for seven Spirulina cultures.

3.2 Biochemical time trends

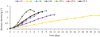

During the experiments, the biochemical contents, including carbohydrate, lipid, protein, PBP, Chl-a, and Cart, were measured daily. The composition of Spirulina biomass undergoes significant changes during different growth phases. Both the factorial and center point runs exhibited similar qualitative trends in biochemical content regarding the growth phases. Therefore, for instance, the results from the center point runs are presented in Figure 2. As shown in Figure 2a, the percentage of carbohydrate increased rapidly to its maximum value of 44.63 ± 0.81% at the very early exponential phase. Subsequently, the percentage decreased and remained constant at 13 ± 0.35% after the middle of exponential phase. During the first day of cultivation, there was a decrease in the protein content of Spirulina. However, as the growth rate increased and the nitrogen source in the medium was consumed, the protein content increased and reached its peak (51.78 ± 0.93%) in the middle of exponential phase. Subsequently, the protein content decreased slowly due to the depletion of nitrogen sources in the medium, and at the end of the culture, it reached 47.63 ± 1.16%. The lipid percentage decreased initially during the culture, but it gradually increased and reached its maximum value at the end of exponential phase (13.10 ± 0.79%).

According to Figure 2b, the levels of Chl-a and Cart contents decreased by 57% and 27% of the initial value, respectively, at the very early exponential phase, and then steadily increased until the end of exponential phase, reaching their maximum values (0.443 ± 0.025% Cart and 2.18 ± 0.13% Chl-a). The PBP content of Spirulina showed a decreasing trend at the very early exponential phase, followed by an increase to its maximum value towards the end of exponential phase (21.12 ± 0.64%). Subsequently, in some experiments, the PBP percentage in the cell decreased or fluctuated.

|

Fig. 2 The time trends of the different biochemical composition of the cell during the CP Spirulina cultures (%, g gCDW−1), a) protein, carbohydrate, and lipid contents, b) different pigment contents. Error bars represent margin of error. |

3.3 Evaluation of factors on maximum content, density, and productivity of biochemical components

During each Spirulina culture, four factorial and three center point runs, the content, density, and productivity of each biochemical component, i.e., carbohydrate, lipid, protein, Chl-a, PBP, and Cart, were measured daily. The maximum values of each measurement and the day of occurrence were selected for further analysis. The effects of the experimental factors, namely light intensity and light exposure time, and their interaction (I.T) on each maximum response were analyzed using analysis of variance (ANOVA). The results are summarized in Table 3.

The effect of light intensity on the maximum content, maximum density, and maximum productivity of each biochemical component was significant, except for maximum Cart content and maximum PBP density. While high light intensity was favorable for achieving maximum density and productivity, it had a negative effect on the maximum content of most biochemical components, with the exception of carbohydrate and Cart. In other words, low light intensity was preferred for increasing the percentage of specific biochemicals in biomass. Conversely, high light intensity was preferred to increase the density or productivity of the same biochemical. With the exception of a few responses, the effect of light exposure time and the interaction of light intensity and light exposure time on the maximum content and density of each biochemical component was negligible. For maximum productivity of biochemical components, all the main factors and their interactions, except for the interaction effect on Cart, had a positive effect on the responses.

The effect of main factors (light intensity and light exposure time) and their interaction (I.T) on maximum content, density, and productivity of Spirulina biochemical components.

3.3.1 Maximum biochemical content

The maximum values of each biochemical content and the corresponding day for each experiment are given in Table 4.

The results from Tables 3 and 4 indicated that the maximum protein content was negatively affected by light intensity. The highest maximum protein content was observed in two factorial experiments with low light intensity, namely, 58.15 ± 0.93% on day 12 for LL and 56.16 ± 1.07% on day 6 for LH experiments, occurring during the middle of their exponential phases. In contrast, light exposure time did not significantly affect the maximum protein content. In the case of the maximum carbohydrate content, both light intensity and the interaction factors exhibited a positive influence. The highest and the lowest maximum carbohydrate content were observed in HH (48.38 ± 0.13%) and LH (37.19 ± 0.39%) experiments, respectively. The carbohydrate content of HL and CP experiments did not differ significantly (approximately 44.5%). Additionally, maximum carbohydrate content was observed for all experiments in the very early exponential phase. Regarding the maximum lipid content, the light intensity had a negative effect, whereas the light exposure time did not show any significant effect. The experiments conducted at low light intensity exhibited a higher maximum lipid content in comparison to those conducted at high light intensity, and both experiments exhibited a higher maximum lipid content than CP experiments conducted at moderate light intensity. Additionally, all the experiments reached maximum lipid content at the end of exponential phase.

Regarding the pigment content, the findings in Tables 3 and 4 revealed that the light intensity was found to be a significant factor affecting the maximum Chl-a content, with a negative effect. The LL experiment showed the highest maximum Chl-a content (2.83 ± 0.16%), followed by the LH experiment (2.60 ± 0.02%). Furthermore, all factorial and CP experiments reached their maximum Chl-a content by the end of the culture time. There was no significant difference observed in the maximum Cart content among the LL, LH, and HL experiments, and they provided a higher maximum amount of Cart compared to the other experiments. The pattern for maximum Cart content based on the studied light intensity and light exposure time levels was not consistent (Tab. 3). Additionally, as indicated in Table 4, the maximum Cart content was achieved at the end of each culture. In terms of the maximum PBP content, the results of the factorial experiments indicated a negative effect of light intensity. However, the presence of curvature in the response showed a non-linear relationship, indicating that the maximum PBP content was obtained in CP experiments. The highest and lowest maximum PBP contents were observed in CP experiments (approximately 21%) and high light intensity experiments (approximately 14%), respectively. The PBP content reached its peak value towards the end of exponential phase for all experiments. For example, in the LL and CP experiments with 20 and 7 days of cultivation, the maximum PBP content was achieved on the 14th and 6th days of Spirulina culture, respectively.

In addition to total PBP, Figure 3 depicts the maximum values and corresponding days of occurrence for the main constituents of PBP. PC had the highest content of cellular PBP, followed by APC and PE in the cell. The maximum content of PBP and its constituents (i.e., PC, PE, and APC) occurred on the same day of cultivation. ANOVA analysis (not shown) revealed that, similar to PBP, light intensity had a negative effect on the constituents of PBP, while light exposure time did not significantly affect them. Additionally, the presence of curvature in responses was detected. However, concerning the maximum content of PE and APC, there was an antagonistic effect observed due to the interaction between light intensity and light exposure time. The maximum PC content was observed in the low light intensity and CP experiments (approximately 11.5%). The highest and lowest maximum APC contents were observed in the CP experiments (7.28 ± 0.66%) and the HH experiment (3.88 ± 0.44%), respectively. The highest level of maximum PE content was observed in CP experiments (2.28 ± 0.42%), and for factorial experiments, the maximum PE contents were not significantly different.

The maximum content of each component and its occurrence day (in parenthesis).

|

Fig. 3 The maximum content of each PBP (PC, APC, and PE) during the Spirulina cultures. The day of culture that each PBP reaches its maximum value is represented above each bar. Error bars represent the margin of error. The same letters above each bar indicate no significant difference between the experiments at a 95% confidence interval (by Tukey’s test, p < 0.05). |

3.3.2 Maximum density of biochemical components

Figure 4 shows the maximum density of cell components. Although most of the biochemical contents were maximized at the low level of light intensity, the effect of light intensity on the maximum density of biochemical components was positive (Tab. 3). Specifically, the density of each component, excluding PBP, achieved its maximum in the HH experiment due to its direct correlation with the highest biomass density observed in the HH experiment (1.68 gCDW L−1). The protein, carbohydrate, lipid, and Chl-a densities in the HH experiment were 0.737 ± 0.009 g L−1, 0.292 ± 0.007 g L−1, 0.240 ± 0.002 g L−1, and 36.65 ± 0.65 mg L−1, respectively. The density of Cart in the HH and HL experiments did not differ significantly, with the maximum densities reaching 8.07 ± 0.38 mg L−1 and 8.35 ± 0.36 mg L−1, respectively. The maximum PBP density was 0.285 ± 0.028 g L−1 for the CP experiments. Interestingly, it was observed that the light exposure time had a greater effect than light intensity on achieving the maximum PBP density (Tab. 3). Specifically, a light exposure time of 16 h in the CP experiments resulted in the highest PBP density (Fig. 4). The density of biochemical components in all runs reached their maximum nearly at the end of the culture due to their relatively high biomass densities.

|

Fig. 4 The maximum density of Spirulina biochemical components (protein, carbohydrate, lipid, Chl-a, Cart, and PBP) in each experiment. Error bars represent the margin of error. The average of all results for three replicates of CP experiments is shown as CPs. The day of the culture that each density of biochemical components reaches its maximum value is represented above the corresponding bar. |

3.3.3 Maximum Productivity of biochemical components

Figure 5 shows the maximum productivity of each biochemical compound obtained from the experiments. The productivity of each compound is influenced by the content of the compound, biomass density, and the duration of cultivation. The HH experiment demonstrated the highest maximum productivity for all compounds, which can be attributed to its higher biomass density and shorter cultivation time. Following the HH experiment, the CP, HL, LH, and LL experiments had the next highest productivity levels, respectively. In the HH experiment, protein productivity was highest on the third day of culture (0.161 ± 0.004 g L−1 d−1), and carbohydrate productivity was highest on the first day of culture (0.094 ± 0.003 g L−1 d−1). The maximum productivity of Lipid (0.050 ± 0.007 g L−1 d−1), Chl-a (8.01 ± 0.19 mg L−1 d−1), Cart (1.73 ± 0.07 mg L−1 d−1), and PBP (0.052 ± 0.003 g L−1 d−1) was obtained on the fourth day in the HH experiment. Moreover, the time to reach the maximum productivity of each biochemical component was different and was close to the time that the content of the desired component was maximized in the cell.

Based on the ANOVA analysis (Tab. 3), all main factors and their interaction exhibited a positive effect on the maximum productivity of all components. The influence of exposure time is evident as the maximum productivity of all components in the HH experiment surpassed that of the HL experiment, and similarly, the LH and LL experiments followed the same trend.

|

Fig. 5 The maximum productivity of Spirulina biochemical component (protein, carbohydrate, lipid, Chl-a, Cart, and PBP) in each experiment. Error bars represent the margin of error. The average of all results for three replicates of CP experiments is shown as CPs. The day of the culture that the productivity of each component reaches its maximum value is represented above the corresponding bar. |

4 Discussion

4.1 Growth characteristics and energy efficiencies

Optimizing the cultivation of Spirulina entails fine-tuning environmental and operational factors to meet specific biochemical needs. Among these factors, light irradiance plays a pivotal role. Manipulating irradiance yields noticeable effects on growth characteristics. Increasing light intensity or exposure time enhances light energy transfer, thereby stimulating photosynthesis and exerting a substantial influence on Spirulina cultivation. In a previous study, it was noted that the growth of Spirulina reached saturation within the range of 150–200 μmol photon m−2 s−1, which corresponded to approximately 10–15% of the total solar irradiance in the 400–700 nm range. Exposure to light intensities exceeding the saturation threshold may lead to a decrease in the rate of photosynthesis, a phenomenon known as photoinhibition (Vonshak and Tomaselli, 2000). Based on this information and the absence of any observed reduction in growth rate with increasing light intensity (as shown in Tab. 2), it can be postulated that no photoinhibition occurred in the present study.

In this study, among the factorial and CP experiments, the experiments involving a high level of both factors, namely light intensity and light exposure time, referred to as the HH experiment, resulted in the highest final biomass density, final biomass productivity, maximum specific growth rate, and the shortest operating time. The effect of light intensities of 101, 135, 162, and 203 μmol photon m−2 s−1 was studied in a Spirulina culture, and it was observed that the highest light intensity resulted in the highest specific growth rate (0.42 ± 0.01 d−1) and biomass density (1.5 gCDW L−1) when the culture was harvested in the stationary phase on day 14 (Dejsungkranont et al., 2017). Also, the obtained result is consistent with other research that has demonstrated that increasing light intensity while maintaining a constant light exposure time and prolonging the light exposure time while keeping the light intensity constant both lead to an improvement in Spirulina’s growth characteristics (Chofamb, 2021; Niangoran et al., 2021; Kumaresan et al., 2020; Xie et al., 2015; Chen et al., 2013; Prates et al., 2018; Ho et al., 2018).

In terms of energy efficiency concerning LEDs, the HH experiment demonstrated the highest level of energy efficiency for biomass. Therefore, increasing light intensity up to photoinhibition level and light exposure time could be a promising strategy for enhancing energy savings in biomass productivity. Additionally, the growth characteristics measured under CP conditions closely resembled those observed under HL conditions. However, the energy efficiency associated with LED lighting for biomass in HL experiments was 15% lower than in CP experiments (Tab. 2). Hence, it is recommended to interchangeably use HL instead of CP to reduce energy consumption and optimize cultivation costs. In another study, using three scenarios of light intensity (80, 160, and modulated intensity 80–160 μmol photon m−2 s−1) in a 25-liter working volume photobioreactor, it was shown that the highest biomass productivity (38.63 ± 1.12 mgCDW L−1 d−1) and specific growth rate (0.1295 ± 0.0008 d−1) obtained under constant light intensity of 160 μmol photon m−2 s−1, whereas the best energy efficiency (1.48 ± 0.05 gCDW d−1 kWh−1) observed in constant light intensity of 80 μmol photon m−2 s−1 (Niangoran et al., 2021), which was very close to the value obtained for the HL experiment.

4.2 Biochemical content

The biological synthesis pathways of protein, lipid, and carbohydrate compete with each other, especially the carbohydrate pathway competes with the lipid (George et al., 2014) and protein (Markou et al., 2019) pathways. Additionally, it has been suggested that to maximize lipid content, it is necessary to reduce the content of carbohydrate and protein (Nzayisenga et al., 2020). So, each biochemical component reaches its maximum level at different stages of growth (Fig. 2a). During the lag phase and very early exponential phase, cells demand substantial energy for biomass accumulation. This prompts a metabolic shift towards carbohydrate synthesis, as well as the potential breakdown of proteins and lipids to generate energy or serve as substrates for carbohydrate pathways. The increase in carbohydrates is seen as a mechanism for cyanobacteria to regulate carbon pools and energy storage, enabling them to adapt their growth to changing environmental conditions (Kromkamp, 1987). In the very early exponential phase, protein and lipid content decrease while carbohydrate content increases, resulting in the highest levels of carbohydrates. The same trends were observed for the cellular biomolecules of Spirulina platensis when studied by Fourier-transform infrared spectroscopy and partial least squares regression (Batallera and Caparedab, 2020). Over time, carbohydrates are utilized as an energy source and converted into other biomolecules such as lipids and proteins. Until the middle of exponential phase, Spirulina efficiently utilizes nitrogen sources in the medium to synthesize proteins essential for growth and cellular processes. During the middle to late exponential phase, when nitrogen sources become limited, there is a metabolic shift toward prioritizing lipid accumulation, leading to maximum lipid content (Metsoviti et al., 2020). However, previous studies have yielded contradictory results regarding lipid measurements. In one study, where lipid content was measured at 5-day intervals over a 20-day fixed cultivation period under different light spectra, it was observed that the lipid content reached its peak on the 10th day in all three cultures. On day 10, the cultures subjected to red and white illumination were in the stationary phase, whereas the culture exposed to blue light was still in the middle of exponential phase (Vo et al., 2017). Conversely, another study reported that in phototrophic conditions, the lipid content increased until the middle of exponential phase, but then decreased until the death phase (Tosuner and Ürek, 2020).

As depicted in Figures 1 and 2b, the Chl-a content is positively correlated with cell density during culture. As the cell density increases, the light penetration decreases due to self-shading. Consequently, the cell increases its photoreceptors, chlorophyll, to enhance photosynthesis (Chofamb, 2021). However, previous studies have reported that the Chl-a content of Spirulina phototrophic culture reaches its maximum in the middle of exponential phase (Tosuner and Ürek, 2020). Regarding carotenoids, the increase in Cart content at the end of exponential phase is due to two reasons: an increase in the primary Cart to capture more light as the biomass concentration increases, and an increase in the secondary Cart to protect the cell from nutritional limitations. The synthesis of PBP is growth-dependent, and its content in the cells is directly proportional to the nitrogen concentration in the culture medium. While the nitrogen source is plentiful, it is utilized for the synthesis of nitrogenous cell components and storage of PBP. However, under nitrogen-depleted conditions, PBP serves as an intracellular nitrogen source, leading to a reduction in its content in the cell (Chen et al., 2013). This finding is consistent with previous studies reporting the maximum content of PC and APC during the exponential phase (Dejsungkranont et al., 2017; Xie et al., 2015; Chen et al., 2013).

Unlike previous papers that focused on investigating the impact of light conditions on the amount of key biochemicals at the end of cultivation and at harvesting time, our study explores the influence of light conditions on the maximum values of each key biochemical. As observed in Table 4 and Figures 2 and 3, it is evident that these maximum values are not limited to the end of cultivation and harvesting time. Instead, they occur at different stages throughout the growth process. Consistent with a previous study that measured the final protein and carbohydrate content of Spirulina after a fixed 14-day cultivation period in the stationary phase (Dejsungkranont et al., 2017), our investigation on the effect of light intensity also revealed that low light intensity resulted in maximum protein content during the middle of exponential phase, while high light intensity led to maximum carbohydrate content in the very early exponential phase. High light intensity generally induces stress on the cell, and energy reaching from photosynthesis is used to synthesize reduced forms of storage compounds instead of proteins (Sui and Harvey, 2021). Furthermore, high light intensity significantly boosted carbohydrate accumulation, accompanied by the upregulation of genes and increased activity of enzymes related to sucrose and starch synthesis, as well as those involved in carbon metabolism (Tang et al., 2022; Xie et al., 2015). Conversely, low light intensities limited the rate of CO2 fixation and ATP production, reducing the cell’s ability to produce excess organic material and energy beyond its immediate protein synthesis needs (Konopka and Schnur, 1980).

In addition, it was shown in this study that exposure time had a negative effect on maximum protein content, which was contrary to findings of another study that observed higher protein content in a culture with continuous illumination compared with a partially illuminated culture (Prates et al., 2018). The discrepancy may be attributed to the harvesting time, as they halted the cultures under different illumination conditions on the same day, while some cultures were in the exponential phase and others in the stationary phase. The findings of this study indicate that exposure time did not have a direct impact on the maximum carbohydrate and maximum lipid content. This result aligns with a previous study that investigated different light spectra and exposure times, where the final lipid and carbohydrate content of cultures remained unaffected by varying exposure times at the same harvesting time (Prates et al., 2018). Lipid accumulation in the cell is low when the light intensity is appropriate for cell growth. Therefore, to attain the maximum lipid content in the cell, the light intensity should be either high or low enough relative to the optimum light intensity. Notably, low light intensity has been found to be more effective in increasing lipid content (George et al., 2014).

Previous studies have reported a decrease in final Chl-a content as light intensity increases. For instance, the Chl-a content decreased from 5.3 ± 0.6% to 2.5 ± 0.7% with increasing light intensity from 101 to 203 μmol photon m−2 s−1 for cultures harvested on day 14 in the stationary phase (Dejsungkranont et al., 2017). Similarly, another study showed a decrease in Chl-a content from 1.27 ± 0.08% to 0.73 ± 0.04% with increasing light intensity from 80 to 160 μmol photon m−2 s−1 for cultures harvested on day 8 in the exponential phase (Niangoran et al., 2021). However, as shown in Table 4, the maximum Chl-a content in CPs and high light intensity experiments did not differ significantly (approximately 2.20%), indicating that the decrease in maximum Chl-a content occurs up to a certain level of light intensity, beyond which further increases in light intensity do not significantly change the maximum Chl-a content. This highlights that when light intensity is too low, the photosystem apparatus size increases to accommodate a higher chlorophyll content, enabling enhanced light absorption for efficient photosynthesis. Furthermore, the maximum Chl-a content exhibited a negative correlation with increasing light exposure time under low light intensity conditions, indicating that the prolongation of light exposure time under low light intensity can decrease the maximum Chl‑a content in Spirulina.

Based on the ANOVA table (Tab. 3), no significant pattern of relationship between light conditions and Cart content was observed. Additionally, previous studies examining the effect of light intensity on Cart content have yielded conflicting findings. For instance, it has been reported that low light intensity resulted in higher Cart content than high light intensity (0.44 ± 0.03% at 80 μmol photon m−2 s−1 and 0.24 ± 0.02% at 160 μmol photon m−2 s−1) when cultures were halted on day 8 during the exponential phase (Niangoran et al., 2021), whereas another study found that Cart accumulation in the final biomass was higher at high light intensity (0.2 ± 0.0% at 101 μmol photon m−2 s−1 and 1.4 ± 0.5% at 203 μmol photon m−2 s−1) when the cultures were harvested on day 14 in the stationary phase (Dejsungkranont et al., 2017). As shown in Table 4, the maximum Cart content was achieved at the end of each culture. Halting the cultivation under different light conditions at the same culture time resulted in a variety of results. Moreover, the contradictory results may be linked to the different Cart functions in the cells, where the primary Cart—as an accessory photosynthesis pigment—is increased in low light intensity to help absorb more light energy for photosynthesis, and the secondary Cart is synthesized in high light intensity or other stress conditions to protect the cell from oxidative damage caused by free radicals and reactive oxygen species (Ren et al., 2021).

Light intensity is the key environmental factor affecting phycobilisomes, which are the light-harvesting complexes in cyanobacteria. Because of the photosensitive nature of PBP, high light intensity decreases the number of chromophore proteins, thereby reducing phycobilisomes per cell. This reduction in phycobilisomes correlates with lower levels of PC, APC, and PE (Jespersen et al., 2005; Nomsawai et al., 1999). Conversely, under low light intensity, the production of PBP increases to enhance light energy absorption, as they can extend the entire absorption band of light. This helps maintain the balance of energy distribution between the two photosystems (Wyman and Fay, 1986). It has been reported that the maximum PC content at different light intensities showed an increase as light intensity decreased (2.2 ± 0.2% under a light intensity of 450 μmol photon m−2 s−1 and 18.4 ± 0.4% at a light intensity of 75 μmol photon m−2 s−1 (Xie et al., 2015). Similar results were also observed in other studies (Dejsungkranont et al., 2017; Chen et al., 2013). However, our findings (Tab. 4, Fig. 3) revealed a non-linear relationship between light intensity and the maximum content of PBP, including PC, APC, and PE, with the highest content observed in CP experiments. Furthermore, the inconsistency in the effect of light intensity and light exposure time on final PC content can also be observed in previous studies, which can be attributed to the use of fixed cultivation time and the oversight of extreme values during the growth period (Chaiklahan et al., 2022; Niangoran et al., 2021; Ho et al., 2018; Prates et al., 2018).

4.3 Biochemical density

Except for maximum PBP density, light intensity positively influenced the maximum density of all key biochemicals (Tab. 2), aligning with previous studies that reported similar positive effects on Chl-a and protein densities (Chofamb, 2021; Chen et al., 2010). The maximum density of PBP was positively affected only by light exposure time. Previous studies also revealed that light intensity did not appear to have a particular effect on PC and APC densities when analyzing samples taken on day 14 in the stationary phase (Dejsungkranont et al., 2017). In another study, it was observed that light intensity had a significant and positive effect on PC density when the cultures were harvested on day 5, where the cultures were at different stages of the exponential phase (Chen et al., 2010). Maximum PBP density was observed at nearly the end of exponential phase in all experiments, at which time considerable biomass density was achieved, and sufficient nitrogen was available in the culture medium, so the cell did not have to degrade PBP to supply nitrogen. This result was in line with other studies (Manirafasha et al., 2018; Dejsungkranont et al., 2017).

4.4 Biochemical productivity

The impact of light intensity, light exposure time, and their interaction on the maximum productivity of all components was positive (Tab. 3). Increasing these factors resulted in shorter culture times, leading to enhanced productivity of biochemical components. This finding aligns with previous studies for maximum PC productivity, which was observed near the end of exponential phase (Xie et al., 2015; Chen et al., 2013; Ho et al., 2018). However, in another study, protein productivities in two different photoperiods using white, green, and blue LEDs were claimed to be not significantly different when the measurements were performed from the samples taken on the 10th day of the culture in the early stationary phase (Prates et al., 2020).

In conclusion, considering the optimal light quantity and best harvesting time is crucial for maximizing specific biochemical components in Spirulina biomass. Increasing light intensity and exposure time, as well as harvesting at the very early exponential phase, enhance carbohydrate content. Conversely, lower light intensity and harvesting at the end of exponential phase promote lipid and Chl-a content. Optimal protein content is achieved with low light intensity, short exposure time, and harvesting during the exponential phase’s midpoint. Maximum PBP content is obtained by moderate light intensity and harvesting near the end of exponential phase. The maximum density of all key biochemicals requires high light intensity and harvesting at the exponential phase’s end. To maximize productivity, high light intensity and high exposure time should be coupled with harvesting when the desired component’s content in the cell is maximized.

Nomenclature

Acknowledgments

This work was supported by Ferdowsi University of Mashhad Graduate Student Research Program [grant number 3/50781].

Conflicts of interest

The authors declare no conflict of interest.

Author contribution statement

A.Maali made significant contributions to the investigation, methodology development, original draft writing, and visualization of the article. R. Gheshlaghi played a crucial role in conceptualizing the study, developing the methodology, providing resources, reviewing and editing the manuscript, and overseeing the project as a supervisor. M.A. Mahdavi contributed to the project by providing valuable resources and scientific comments for the study.

References

- Altmann B, Rosenau S. 2022. Spirulina as animal feed: opportunities and challenges. Foods, 11(7): 965. [CrossRef] [PubMed] [Google Scholar]

- Andrade AFd, Porto ALF, Bezerra RP. 2022. Photosynthetic microorganisms and their bioactive molecules as new product to healing wounds. Appl Microbiol Biotechnol 106: 497–504. [CrossRef] [PubMed] [Google Scholar]

- Batallera BG, Caparedab SC. 2020. Use of FTIR spectroscopy and PLS-regression in monitoring biomolecules in Spirulina platensis during its growth in an internally-illuminated photobioreactor. CET 80: 103–108. [Google Scholar]

- Bennett A, Bogard L. 1973. Complementary chromatic adaptation in a filamentous blue-green alga. J Cell Biol 58: 419–435. [CrossRef] [PubMed] [Google Scholar]

- Chaiklahan R, Chirasuwan N, Srinorasing T, Attasat S, Nopharatana A, Bunnag B. 2022. Enhanced biomass and phycocyanin production of Arthrospira (Spirulina) platensis by a cultivation management strategy: Light intensity and cell concentration. Bioresour Technol 343: 126077. [Google Scholar]

- Chen CY, Kao PC, Tsai CJ, Lee DJ, Chang JS. 2013. Engineering strategies for simultaneous enhancement of C-phycocyanin production and CO2 fixation with Spirulina platensis. Bioresour Technol 145: 307–312. [CrossRef] [PubMed] [Google Scholar]

- Chen HB, Wu JY, Wang CF, et al. 2010. Modeling on chlorophyll a and phycocyanin production by Spirulina platensis under various light-emitting diodes. Biochem Eng J 53: 52–56. [CrossRef] [Google Scholar]

- Chen HY, Chiang YF, Huang CY, et al. 2022. Spirulina phycocyanin extract and its active components suppress epithelial-mesenchymal transition process in endometrial cancer via targeting TGF-beta1/SMAD4 signaling pathway. Biomed Pharmacother 152: 113219. [Google Scholar]

- Chofamb A. 2021. Cellular bioenergetics in Spirulina platensis towards growth and phycocyanin production under different photon flux densities using the modified Zarrouk’s medium. TURJAF 9: 28–34. [Google Scholar]

- Cui H, Yang Z, Lu Z, Wang Q, Liu J, Song L. 2019. Combination of utilization of CO2 from flue gas of biomass power plant and medium recycling to enhance cost-effective Spirulina production. J Appl Phycol 31: 2175–2185. [CrossRef] [Google Scholar]

- Dehghani J, Adibkia K, Movafeghi A, et al. 2018. Stable transformation of Spirulina (Arthrospira) platensis: a promising microalga for production of edible vaccines. Appl Microbiol Biotechnol 102: 9267–9278. [CrossRef] [PubMed] [Google Scholar]

- Dejsungkranont M, Chisti Y, Sirisansaneeyakul S. 2017. Simultaneous production of C-phycocyanin and extracellular polymeric substances by photoautotrophic cultures of Arthrospira platensis. J Chem Technol Biotechnol 92: 2709–2718. [Google Scholar]

- Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F. 1956. Colorimetric method for determination of sugars and related substances. Anal Chem 28: 350–356. [CrossRef] [Google Scholar]

- George B, Pancha I, Desai C, et al. 2014. Effects of different media composition, light intensity and photoperiod on morphology and physiology of freshwater microalgae Ankistrodesmus falcatus − a potential strain for bio-fuel production. Bioresour Technol 171: 367–374. [CrossRef] [PubMed] [Google Scholar]

- Glemser M, Heining M, Schmidt J, et al. 2016. Application of light-emitting diodes (LEDs) in cultivation of phototrophic microalgae: current state and perspectives. Appl Microbiol Biotechnol 10: 1077–1088. [CrossRef] [PubMed] [Google Scholar]

- Guldas M, Ziyanok-Demirtas S, Sahan Y, Yildiz E, Gurbuz O. 2020. Antioxidant and anti-diabetic properties of Spirulina platensis produced in Turkey. Food Sci Technol 41: 615–625. [Google Scholar]

- Haghighi M, Zare LB, Ghiasi M. 2022. Biodiesel production from Spirulina algae oil over [Cu(H2PDC)(H2O)2] complex using transesterification reaction: experimental study and DFT approach. Chem Eng J 430: 132777. [Google Scholar]

- Hea X, Wang C, Zhu Y, et al. 2022. Spirulina compounds show hypoglycemic activity and intestinal flora regulation in type 2 diabetes mellitus mice. Algal Res 66: 102791. [Google Scholar]

- Ho SH, Liao JF, Chen CY, Chang JS. 2018. Combining light strategies with recycled medium to enhance the economic feasibility of phycocyanin production with Spirulina platensis. Bioresour Technol 247: 669–675. [CrossRef] [PubMed] [Google Scholar]

- Iamtham S, Sornchai P. 2022. Biofixation of CO2 from a power plant through large-scale cultivation of Spirulina maxima. S Afr J Bot 147: 840–851. [CrossRef] [Google Scholar]

- Jara Adl, Ruano-Rodriguez C, Polifrone M, et al. 2018. Impact of dietary Arthrospira (Spirulina) biomass consumption on human health: main health targets and systematic review. J Appl Phycol 30: 2403–2423. [CrossRef] [Google Scholar]

- Jespersen L, Strømdahl LD, Olsen K, Skibsted LH. 2005. Heat and light stability of three natural blue colorants for use in confectionery and beverages. Eur Food Res Technol 220: 261–266. [CrossRef] [Google Scholar]

- Jin SE, Lee SJ, Park CY. 2020. Mass-production and biomarker-based characterization of high-value Spirulina powder for nutritional supplements. Food Chem 325: 126751. [Google Scholar]

- Konopka A, Schnur M. 1980. Effect of light intensity on macromolecular synthesis in cyanobacteria. Microbial Ecology 6: 291–301. [CrossRef] [PubMed] [Google Scholar]

- Kromkamp J. 1987. Formation and functional significance of storage products in cyanobacteria. N. Z. J Mar Freshw Res 21: 457–465. [CrossRef] [Google Scholar]

- Kumaresan G, Sivakumar K, Singh RLF. 2020. Effect of abiotic factors on the growth of Spirulina Platensis strains. Plant Arch 20: 4259–4263. [Google Scholar]

- Li X, Manuel J, Slavens S, Crunkleton DW, Johannes TW. 2021. Interactive effects of light quality and culturing temperature on algal cell size, biomass doubling time, protein content, and carbohydrate content. Appl Microbiol Biotechnol 105: 587–597. [CrossRef] [PubMed] [Google Scholar]

- Lowry OH, Rosebrough NJ, Farr AL, Randall RJ. 1951. Protein measurement with the Folin phenol reagent. J Biol Chem 193: 265–275. [CrossRef] [PubMed] [Google Scholar]

- Manirafasha E, Murwanashyaka T, Ndikubwimana T, et al. 2018. Enhancement of cell growth and phycocyanin production in Arthrospira (Spirulina) Platensis by metabolic stress and nitrate fed-batch. Bioresour Technol 225: 293–301. [CrossRef] [PubMed] [Google Scholar]

- Markou G, Kougia E, Kefalogianni I, Tsagou V, Arapoglou D, Chatzipavlidis I . 2019. Effect of glycerol concentration and light intensity on growth and biochemical composition of Arthrospira (Spirulina) platensis: A study in semi-continuous mode with non-aseptic conditions. Appl Sci 9(21): 4703. [Google Scholar]

- Mata SN, Santos TdS, Cardoso LG, et al. 2020. Spirulina sp. LEB 18 cultivation in a raceway-type bioreactor using wastewater from desalination process: production of carbohydrate-rich biomass. Bioresour Technol 311: 123495. [Google Scholar]

- Metsoviti MN, Papapolymerou G, Karapanagiotidis IT, Katsoulas N. 2020. Effect of light intensity and quality on growth rate and composition of Chlorella vulgaris. plants 9(1): 31. [PubMed] [Google Scholar]

- Mishra SK, Suh WI, Farooq W, et al. 2014. Rapid quantification of microalgal lipids in aqueous medium by a simple colorimetric method. Bioresour Technol 155: 330–333. [CrossRef] [PubMed] [Google Scholar]

- Moon S, Lee Y-J, Choi M-Y, Lee C-G, Park S-J. 2023. Adsorption of heavy metals and bisphenol A from wastewater using Spirulina sp.-based biochar as an effective adsorbent: a preliminary study. J Appl Phycol 35: 2257–2269. [CrossRef] [Google Scholar]

- Niangoran NgUF, Buso D, Zissis G, Prudhomme T. 2021. Influence of light intensity and photoperiod on energy efficiency of biomass and pigment production of Spirulina (Arthrospira platensis). OCL 28: 37. [Google Scholar]

- Niangoran NU, Canale L, Tian F, Haba TC, Zissis G. 2019. Optimal spectrum modeling calculation with light emitting diodes set based on relative quantum efficiency. Acta Hortic 1242: 815–822. [CrossRef] [Google Scholar]

- Niangoran U, Tian F, Canale L, Haba CT, Buso D, Zissis G. 2018. Study of the LEDs spectrums influence on the Spirulina platensis growth in batch culture. In: IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC / I&CPS Europe), 1–4. Palermo, Italy. [Google Scholar]

- Nomsawai P, Marsac NTd, Thomas JC, Tanticharoen M, Cheevadhanarak S. 1999. Light regulation of phycobilisome structure and gene expression in Spirulina platensis Cl (Arthrospira sp. PCC 9438). Plant Cell Physiol 40: 1194–1202. [CrossRef] [Google Scholar]

- Nzayisenga JC, Farge X, Groll SL, Sellstedt A. 2020. Effects of light intensity on growth and lipid production in microalgae grown in wastewater. Biotechnol Biofuels 13: 4. [PubMed] [Google Scholar]

- Prates DdF, Duarte JH, Vendruscolo RG, et al. 2020. Role of light emitting diode (LED) wavelengths on increase of protein productivity and free amino acid profile of Spirulina sp. cultures. Bioresour Technol 306: 123184. [Google Scholar]

- Prates DdF, Radmann EM, Duarte JH, Morais MGd, Costa JAV. 2018. Spirulina cultivated under different light emitting diodes: enhanced cell growth and phycocyanin production. Bioresour Technol 256: 38–43. [CrossRef] [PubMed] [Google Scholar]

- Ragaza JA, Hossain MS, Meiler KA, Velasquez SF, Kumar V. 2020. A review on Spirulina: alternative media for cultivation and nutritive value as an aquafeed. Rev Aquac 12: 2371–2395. [CrossRef] [Google Scholar]

- Raji AA, Jimoh WA, Bakar NHA, et al. 2020. Dietary use of Spirulina (Arthrospira) and Chlorella instead of fish meal on growth and digestibility of nutrients, amino acids and fatty acids by African catfish. J Appl Phycol 32: 1763–1770. [CrossRef] [Google Scholar]

- Rempel A, Sossella FdS, Margarites AC, et al. 2019. Bioethanol from Spirulina platensis biomass and the use of residuals to produce biomethane: an energy efficient approach. Bioresour Technol 288: 121588. [Google Scholar]

- Ren Y, Sun H, Deng J, Huang J, Chen F. 2021. Carotenoid production from microalgae: biosynthesis, salinity responses and novel biotechnologies. Mar Drugs 19(12): 713. [Google Scholar]

- Si WqS, Gao dL, Wen.hua rL, Qing W, Yong xC, Ling qLXw. 2016. Investigation of main factors affecting the growth rate of Spirulina. Optik 127: 6688–6694. [CrossRef] [Google Scholar]

- Solis.Méndez A, Molina.Quintero M, Rosa EODl, Cantú.Lozano D, Bianchi VLD. 2020. Study of agitation, color and stress light variables on Spirulina platensis culture in vertical stirred reactor in standard medium. Rev Mex Ing Quim 19: 481–490. [Google Scholar]

- Sui Y, Harvey PJ. 2021. Effect of light intensity and wavelength on biomass growth and protein and amino acid composition of Dunaliella Salina. Foods 10(5): 1018. [PubMed] [Google Scholar]

- Tang W, Guo H, Baskin CC, et al. 2022. Effect of light intensity on morphology, photosynthesis and carbon metabolism of alfalfa (Medicago sativa) seedlings. plants 11(13): 1688. [PubMed] [Google Scholar]

- Tosuner ZV, Ürek RÖ. 2020. Evaluation of sucrose as carbon source in mixotrophic culture of Arthrospira platensis Gomont 1892. Aquat Res 3: 1–12. [CrossRef] [Google Scholar]

- Tzachor A, Rozen O, Khatib S, Jensen S, Avni D. 2021. Photosynthetically controlled Spirulina, but not solar Spirulina, inhibits TNFα secretion: potential implications for COVID19 related cytokine storm therapy. Mar Biotechnol 23: 149–155. [CrossRef] [PubMed] [Google Scholar]

- Vo T, Nguyen N, Huynh P, et al. 2017. The growth and lipid accumulation of Spirulina sp. Under different light conditions. World J Food Sci Technol 1: 101–104. [Google Scholar]

- Vonshak A. 1997. Spirulina platensis (Arthrospira): physiology, cell-biology and biotechnology, Taylor & Francis. [CrossRef] [Google Scholar]

- Vonshak A, Tomaselli L. 2000. Arthrospira (Spirulina): systematics and ecophysioiogy, New York: Kluwer Academic Publishers. [Google Scholar]

- Wang Q, Liu W, Li X, Wang R, Zhai J. 2019. Carbamazepine toxicity and its co-metabolic removal by the cyanobacteria Spirulina platensis. Sci Total Environ 706: 135686. [Google Scholar]

- Wellburn AR. 1994. The spectral determination of chlorophylls a and b, as well as total carotenoids, using various solvents with spectrophotometers of different resolution. J Plant Physiol 144: 307–313. [CrossRef] [Google Scholar]

- Wuang SC, Khin MC, Chua PQD, Luo YD. 2016. Use of Spirulina biomass produced from treatment of aquaculture wastewater as agricultural fertilizers. Algal Res 15: 59–64. [CrossRef] [Google Scholar]

- Wyman M, Fay P. 1986. Underwater light climate and the growth and pigmentation of planktonic blue-green algae (Cyanobacteria) I. The influence of light quantity. Proc Royal Soc London Ser B, Biolog Sci 227: 367–380. [Google Scholar]

- Xie Y, Jin Y, Zeng X, Chen J, Lu Y, Jing K. 2015. Fed-batch strategy for enhancing cell growth and C-phycocyanin production of Arthrospira (Spirulina) platensis under phototrophic cultivation. Bioresour Technol 180: 281–287. [CrossRef] [PubMed] [Google Scholar]

- Zarrouk C. 1966. ’Contribution a l’etude d’une Cianophycee : influence de divers facteurs physiques et chimiques sur la croissance et la Photosynthese de Spirulina Maxima (Setch. et Garndner) Geitler’, Université De Paris. [Google Scholar]

- Zhang S, Liu Z. 2021. Advances in the biological fixation of carbon dioxide by microalgae. J Chem Technol Biotechnol 96: 1475–1495. [CrossRef] [Google Scholar]

- Zhu B, Xiao T, HanShen. et al. 2021. Effects of CO2 concentration on carbon fixation capability and production of valuable substances by Spirulina in a columnar photobioreactor. Algal Res 56(2): 102310. [Google Scholar]

Cite this article as: Maali A, Gheshlaghi R, Mahdavi MA. 2024. Maximizing key biochemical products of Spirulina platensis: optimal light quantities and best harvesting time. OCL 31: 21.

All Tables

The effect of main factors (light intensity and light exposure time) and their interaction (I.T) on maximum content, density, and productivity of Spirulina biochemical components.

All Figures

|

Fig. 1 The cell growth curve of Spirulina platensis under different light conditions. |

| In the text | |

|

Fig. 2 The time trends of the different biochemical composition of the cell during the CP Spirulina cultures (%, g gCDW−1), a) protein, carbohydrate, and lipid contents, b) different pigment contents. Error bars represent margin of error. |

| In the text | |

|

Fig. 3 The maximum content of each PBP (PC, APC, and PE) during the Spirulina cultures. The day of culture that each PBP reaches its maximum value is represented above each bar. Error bars represent the margin of error. The same letters above each bar indicate no significant difference between the experiments at a 95% confidence interval (by Tukey’s test, p < 0.05). |

| In the text | |

|

Fig. 4 The maximum density of Spirulina biochemical components (protein, carbohydrate, lipid, Chl-a, Cart, and PBP) in each experiment. Error bars represent the margin of error. The average of all results for three replicates of CP experiments is shown as CPs. The day of the culture that each density of biochemical components reaches its maximum value is represented above the corresponding bar. |

| In the text | |

|

Fig. 5 The maximum productivity of Spirulina biochemical component (protein, carbohydrate, lipid, Chl-a, Cart, and PBP) in each experiment. Error bars represent the margin of error. The average of all results for three replicates of CP experiments is shown as CPs. The day of the culture that the productivity of each component reaches its maximum value is represented above the corresponding bar. |

| In the text | |

Les statistiques affichées correspondent au cumul d'une part des vues des résumés de l'article et d'autre part des vues et téléchargements de l'article plein-texte (PDF, Full-HTML, ePub... selon les formats disponibles) sur la platefome Vision4Press.

Les statistiques sont disponibles avec un délai de 48 à 96 heures et sont mises à jour quotidiennement en semaine.

Le chargement des statistiques peut être long.