| Issue |

OCL

Volume 31, 2024

Extraction solvents / Solvants d’extraction

|

|

|---|---|---|

| Article Number | 27 | |

| Number of page(s) | 10 | |

| DOI | https://doi.org/10.1051/ocl/2024021 | |

| Published online | 25 November 2024 | |

Review

Economics of oilseed crushing: assessing the impact of solvent-free processing on added value☆

Économie de la trituration : évaluation de l’impact du non-recours aux solvants sur la valeur ajoutée

Terres Inovia, 11 rue G. Monge, 33610 Canéjan, France

* Corresponding author: p.carre@terresinovia.fr

Received:

19

June

2024

Accepted:

9

September

2024

While it is clear that solvent extraction (SE) dominates the vegetable oil production sector because of the higher yields it allows, it is more difficult to estimate the difference in added value (AV) between this production method and extraction by mechanical means alone (ME). The aim of this article is to propose an objective method for assessing this differential by addressing the question of assessing the material balances associated with each process and the issue of the value of expeller cakes in different economic contexts, an assessment made necessary by the absence of regular public quotations for these feedstuffs. Material balances are determined by the oil content in the seeds and the oil residues left in SE meals and ME cakes. Based on 100 kg of seeds, oil production was estimated at 43.7 and 44.9 kg using the SE process compared with 39.3 and 38.8 kg using the ME process for rapeseed and sunflower respectively. To assess the value of expeller cakes, we used a basket of feedstuffs with known quotations and nutritional value to determine an equation for price prediction within 35 market conjunctures between June 2008 and May 2024. These predictions were used to establish a linear correlation between hexane meal prices and predicted expellers prices allowing a calculation of the added value in 574 market situations from 2010 to 2024. A linear regression shows that AV of ME is equal to 0.71 AV of SE + 6.8 €/t for rapeseed and 0.63 AV of SE + 2.1 €/t for sunflower.

Résumé

S’il est clair que l’extraction par solvant (ES) domine le secteur de la production d’huile végétale en raison des rendements plus élevés qu’elle permet, il est plus difficile d’estimer la différence de valeur ajoutée (VA) entre ce mode de production et l’extraction par les seuls moyens mécaniques (EM). L’objectif de cet article est de proposer une méthode objective d’évaluation de ce différentiel en abordant la question de l’évaluation des bilans matière associés à chaque procédé et la question de la valeur des tourteaux expellers dans différents contextes économiques, évaluation rendue nécessaire par l’absence de cotations publiques régulières de ces aliments. Les bilans matières sont déterminés par la teneur en huile des graines et les résidus d’huile laissés dans les tourteaux ES et EM. En partant de 100 kg de graines, on a évalué la production d’huile à 43.7 et 44.9 kg avec le procédé SE contre 39.3 et 38.8 kg avec le procédé ME pour respectivement colza et tournesol. Pour évaluer la valeur des tourteaux expellers, nous avons utilisé un panier de produits utilisés en alimentation animale dont les cotations et la valeur nutritionnelle sont connues pour déterminer une équation de prédiction des prix dans 35 conjonctures de marché entre juin 2008 et mai 2024. Ces prévisions ont été utilisées pour établir une corrélation linéaire entre les prix du tourteau SE et les prix prédits des expellers, ce qui a permis de calculer la valeur ajoutée dans 574 situations de marché entre 2010 et 2024. Une régression linéaire montre que la VA de la EM est égale à 0,71 VA de l’ES + 6,8 €/t pour le colza et à 0,63 VA de la ES + 2,1 €/t pour le tournesol.

Key words: Crushing / mechanical extraction / solvent extraction / economics / added value

Mots clés : Trituration / Extraction Mécanique / Extraction par Solvant / Economie / Valeur Ajoutée

© P. Carré, Published by EDP Sciences, 2024

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Highlights

Mechanical extraction yields 10-12% less oil than solvent extraction for rapeseed and sunflower processing.

Added value of mechanical extraction is about 30% lower than solvent extraction on average.

Sunflower would be more impacted than rapeseed by the inability to use solvents, due to the relative importance of oil in its value.

Variability in expeller oil content indicates potential for improvement in mechanical extraction, but limitations remain.

1 Introduction

In his book “L’Huilerie Moderne” printed in 1984, Jean Laisney wrote: “Given the power used to increase the pressure and the resulting wear (without, however, reaching a residual oil content of the cakes of less than 5%), high pressure solutions have not been maintained in large capacity plants. It was preferable to reduce this pressure to the level where the wear and power used were lowest and to supplement it by dissolving the remaining oil with a solvent.” Since the generalisation of the SE in large oil-mills, the “full pressing” technology has been reserved to small oilseeds processing units producing speciality oils, or in the “organic” sector where he use of petrosourced solvent is banned. It subsides also in places where oilseeds processing is made with the preservation of feedstuff identity, generally with warranties of non-GM origin. This motivation has led to renewed interest in this technology in recent years, particularly for the production of home-grown soya meal. Figure 1 shows the development of hexane-free crushing capacity in France. The ‘organic’ and soya sectors account for a large proportion of this expansion, but do not represent all the recent units, some of which have the capacity to process soya, rapeseed and sunflower, with the ability to dehull for the production of protein-rich meal. The advantage of these new production units is that they will be able to process the seeds locally to supply livestock farms with quality labels, where the local origin of the feed is valued. The ability of these oil-mills to limit the distances travelled by seeds and expeller cakes is an asset that could motivate certain economic players to build more units of this type, which would compete with the large industrial facilities that use hexane. The power of competition between these two production methods is mainly determined by oil yields. Since oil is the most expensive product obtained from crushing oilseeds, obtaining lower yields reduces the crusher’s added value in the case of ‘full-press’ technology, added value (AV) being defined as the difference between the sum of sales of the crushing products (oil and meal) and the purchase price of the seeds. However, it is quite difficult to assess this difference in added value, given that the oil remaining in the meal gives it an additional value which must be taken into account to establish a reliable assessment of this loss of added value.

Pearson in 1919 wrote that the operating cost in oilseed crushing industry using hydraulic presses were of about 1£/t of oilseed which was 8% of the cost of the crushed oilseed cost. A typical press-cake had between 5% and 10% of oil content (peanut or sesame). On the other hand, the operation with solvent (petroleum ether in general) was costlier (about 12.5% of seed cost) because of solvent losses and a higher consumption of coal. The meals obtained after SE were still having a faint smell of solvent which was detrimental to the value of the product.

Cheng et al. (2019) reviewed the available literature about the economics of plant oil recovery. Their study aimed at the comparison of farm-scale processing, industrial ME and SE. Without surprise, the authors observe that hexane extraction is the dominant process because of high oil recovery and comparatively low operating costs. It also highlights that transportation costs and the credits for coproducts are playing an important role in the economics of crushing. Unfortunately, if the authors say that expellers cake have a higher economical value, they do not elaborate on the issue and give no clues about the level of this higher value. Another article by Cheng and Rosentrater (2017) in which the comparison focuses on soybean crushing by solvent versus extrusion-expelling and aqueous extraction shows that ME becomes profitable beyond the annual capacity production of 12 kt/year of oil versus 173 kt/year for SE. The assessment is based on a rather large difference in the price of expellers and solvent meals of 0.62 versus 0.45 $/kg in 2010–2015 conditions. The source cited by the authors for justifying the values is a USDA statistic including solvent meal prices but in which the prices for expellers cannot be found. The gap in prices represents 37% of solvent meal price which could be justified by immaterial attributes like a “solvent-free” label or a local origin or by an improved nutritional quality, but the rationales of this gap are not explained. Other articles by this first author made in the frame of a doctorate were not giving further details about this question (Cheng et al., 2018; Cheng and Rosentrater, 2019).

St-Pierre and Glamocic (2000) published a method for assessing the breakeven feedstuffs prices based on the extension of the Peterson method which dates back to 1932 with some improvements made to overcome its limitations. Working in the field of ruminants nutrition, their goal was to make a comparison between the actual price of a large range of feedstuffs with an estimated price based a polynomial in which each nutritional criterion is multiplied by an estimator of its contribution to the price of the product. These estimators are assessed on the basis of a matrix X of 25 feedstuffs containing the value in 4 nutrients for each feedstuff (neutral detergent fibre, rumen undegradable and degradable proteins, and net energy content). The price of each material is the vector Y.

The vector b contains four estimators (K1 to K4) which represent the contribution of each nutrient to the feedstuff price.

B is the vector resulting from the matrix product of the matrix X by the vector b. It contains the predicted prices of each feedstuff. Technically, this calculation is the equivalent of a linear regression by the least squares methods (Tranchefort, 1974). The authors show that by taking a wide variety of raw materials, some of which have specific characteristics that have little to do with the ruminant feed market (for example, fish meals, the price of which is driven by demand in aquaculture), a fairly large residual error is generated, which can be reduced by excluding these outliers. In their example, they removed tallow, fish meal, cottonseeds, blood meal and feather meal. Dropping these materials improved the determination coefficient (R2) from 0.61 to 0.83. In another example, St-Pierre (2003), split NDF in non-effective NDF and effective-NDF for refining the prediction and obtained a R2 correlation of 0.75.

Fisher and Schruben (1953) began to present the applications of linear programming to animal feed and showed how the method made it possible to optimise the cost of a feed as a function, on the one hand of the constraints to which the feed must respond and, on the other, of knowledge of the characteristics of the various feeds available on the market and their price. On the basis of these data, they showed that it was possible to define price thresholds above which an ingredient could be used in a particular feed. The method also allows considering the volumes of supply and demand and allocating each raw material to the formulas that best valorise them. This approach was subsequently developed and refined by feed formulation professionals who use it daily in choosing the ingredients that make up the mixes used in a wide range of animal feeds, taking into account a very large number of constraints expressed as maximums and minimums, ranging from metabolizable energy to digestible amino acids, including different fibres, anti-nutritional factors, and various bioavailable minerals and vitamins (Pesti and Miller, 1993; Tröster et al., 2023). proposed a “user-friendly Linear programming-based decision support system (DSS)” for assessing the price of white lupine in Germany. Their method remains relatively complex and gives prediction which vary broadly according to the nutritional needs of each animal production. These approaches require a lot of specific knowledge and necessitate the use of proprietary software that limits the availability of the estimations to the large public. That is why, we turned toward another method which is close to the one proposed by St-Pierre et Glamocic for the predicting the expeller-cake market value relying on more accessible information.

This article aims at supplying a method for assessing this differential in added value between the two model of processing. The question of the processing costs is not addressed here because it would be difficult to compare two technologies that are not used on the same scales and assessing the capital costs would require an access to strategic economic data that are covered by the secret of business.

|

Fig. 1 Cumulative capacity of crushing units operating solely by mechanical extraction in France. |

2 Extraction yields and cake quality

To assess the level of performance in terms of capacity to extract the oil of the seeds, the best way is to look at the level of oil residues in the expeller press cake and to the criteria regarding the feed value of these expeller cakes. Table 1 gives the dry matter (DM) and oil content, the antinutritional factors and proteins solubility of expellers cakes found in databases and a few scientific publications that reflect the performances of commercial screw presses. Regarding DM, this overview shows that most of the time, the expeller cakes are dryer than the hexane extracted meals which are wet at the end of the desolventization step and must be dried below 12% of water content to be safely stored. The standard deviation of DM in expellers is rather large compared to those of hexane meals (σ = 1.0, 1.2 and 0.9 for rapeseed, sunflower and soybean hexane meals versus 2.3, 2.2 and 1.9 for the expellers). This variability is even more large regarding the oil content of the expeller cakes. The lowest value was found in the NRC-2001 table for canola with an average value of 5.4 and a standard deviation of 5.5. This value is likely to be contaminated by results of hexane extracted meals since expellers with oil content lower than 5% are uncommon and the value given by the NANP (2024) database (11.2%) greatly differs. The distribution of the data around the means is asymmetrical since the minimum values falls closer to the mean than the maximum values. It is therefore difficult to give a representative range of performances. Table 1 shows that the data from IO7 (Association Française de Zootechnie, 2024) are relatively close to international data for the oil residues in oilcakes and can be retained for the rest of the study. Organic press-cakes are containing more oil than their conventional equivalent. It is explained by the fact that organic oils are often marketed as virgin oils and that only cold pressing is possible to produce virgin oils while ME without thermal conditioning is less efficient. Regarding the antinutritional factors, it seems that soybeans expellers are containing more trypsin inhibitors than hexane meals (8.6 vs. 5.2 TUI/mg) while their proteins solubilities (KOH) are lower (80 vs. 74%). The wet cooking occurring in the desolventizers is performing better on these beans than dryer-cookers used before ME. In the case of rapeseed, the glucosinolates content of expellers is also higher than for solvent extracted meals (15 vs. 8 μMol/g) but the proteins solubilities (KOH) are much higher (80 vs. 46%). Desolventizing rapeseed is more difficult than desolventizing soybean or sunflower, so, longer residence times are required which results in lower proteins solubilities and lower GLS (Wolff, 1983; Carré, 2021). However, these higher GLS contents do not seem to reach levels likely to affect the value of the oilcake and we will assume that they will not affect its selling price. With oilseeds containing high oil content (linseed, rapeseed/canola and sunflower), the most common yield values are ranging between 80% and 90%. With soybeans, yields are lower and ranging between 60% and 75%. Compared to hexane extraction which result in meals containing oil content below 2%, the yields are ranging between 96–98% for rapeseed, 97–99% for sunflower and about 92% for soybean.

Beyond yields, ME is also characterized by higher variability in the water and oil content which is a cause of incertitude for the feed users and generally leads to a reduction of the value of the proteins meals.

In their literature review about mechanical oil extraction Savoire et al. (2013) have gathered the typical oil residues in press-cakes communicated by screw-press suppliers. For Anderson, they range between 5% and 7%, 5% for Harburg Freudenberger, 8–9% for La Mécanique Moderne (Olexa). Even if the performances claimed by the suppliers are unequal, a significant gap remains between these theoretical performances and the real ones. This discrepancy can be explained by a number of factors, including the fact that the suppliers’ performance figures are based on wear-free presses operating with optimally conditioned seeds and feeding the press at its nominal capacity, whereas the actual figures are based on presses with average wear levels and operating with sub-optimal conditioning as a result of the economic need to minimise energy consumption and maximise throughput. For more details on the possibilities and limitations of ME, readers may refer to our article on this subject published in the same journal (Carré, 2022).

Overview of the proximal composition of expeller cakes.

2.1 Assessment of mater balance and added value

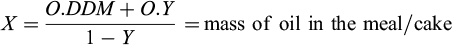

In terms of added value generated by the oil-mill, the lower oil yields of ME are the cause of reduced value of the products resulting from the crushing. Its calculation requires a reliable assessment of the matter balance and of the value of expeller-cakes which are not publicly quoted. Oil and protein meal yields can be assessed from the composition data of the seeds and the meals/cakes assuming no losses during the crushing except at the level of the water which can vary because of the drying/moisturizing caused by the process.

2.2 Calculation of the amount of meal/cake resulting from the crushing (Z).

With H: moisture content in the seeds (g/g), F: oil content in the seeds (g/g), DDM: defatted dry matter in the seeds, X amount of oil in the cake resulting of the processing of the seeds, Y: amount of water in the cake.

X and Y are calculated after resolving the equation system

With Sv: seeds value, Mv: meal value, Ov: oil value and Ev: expeller cake value; WE, WM, OE, OM: the water and oil content of expellers and meals (Tab. 2).

The oil and water content of the seeds can be found in the quality survey published in France by Terres Inovia each year. Since the oil content were given in “standardised” seeds at 9% of water and 2% of impurities, these figures have to be recalculated according to the real impurities and water content. Table 2 recapitulates these data for rapeseed and sunflower.

On the basis of these compositions and the equations (3) to (9), it is possible to determine the matter balance for the processing of 100 kg of seeds according to SE and ME. Tables 2 and 3 gives the results of these calculations. The differential in terms of oil recovery given in the last column shows that 4.4 and 6.1 kg of oil for 100 kg of seeds are not extracted in respectively rapeseed and sunflower press-cakes.

This lesser oil production is likely to reduce the added value of ME but to have a substantial idea of that loss, it is necessary to consider the higher mass of expeller and its change in value related to its higher energy value.

Average water and oil content in rapeseed and sunflower according to the Terres Inovia survey from 2014 to 2022, Feedbase/IO7 for solvent extracted meals and expeller cakes (not for the Seeds).

Matter balance for the processing of 100 kg of seeds according to solvent extraction and mechanical extraction.

3 Assessment of the value of expeller-cakes

The quotations of seeds, oils and solvent extracted meals are regularly published but with the expeller which are not marketed on the same scale we don’t dispose of the same information. In consequence to assess this value, we have used the method proposed by St-Pierre and Glamocic (2000) like in a previous article on the techno-economic feasibility of the rapeseed dehulling where it was used for assessing the potential value of dehulled rapeseed meal (Carré et al., 2015). In brief, it consists in using a basket of commodities which quotations are available and which proximate composition is known to determine an equation of price prediction (Eq. (12)).

With

, predicted value of the commodity i,

, predicted value of the commodity i,Pi, Proteins content of the commodity i,

Oi, Oil content of the commodity i,

NDAi, neutral detergent fiber of the commodity i,

Li, lignin content of the commodity i,

K1 to K5 are coefficient adjusted to minimize the sum of the square of the differences between predicted values and real quotations.

The quotations of commodities are evolving with the time, so the determination is valid only for a given conjuncture and the adjustment must be established for each period.

This method is disputable since the nutritional value of the residual oil as animal feed is not the same as the oil contained in the seed awaiting to be extracted for use as food or as biodiesel. Its utility is limited to the energy supply which is in competition with starch energy which is cheaper in terms of energy supply. In consequence, another approach for assessing the valuation of the expeller will use nutritional criteria. A second prediction equation (Eq. (13)) was used for comparison.

With:

ME, metabolizable energy for growing pigs,

DIG proteins digestibility for growing pigs.

Growing pigs values have been chosen because, these animals are likely to be the best target for expellers cakes. Moreover, these parameters are available for all the feedstuffs, which is not true for other more specific indicators.

Technically, the calculations were made using an Excel spreadsheet and the K and K’ coefficients were determined by using of the solver provided by Excel to minimise the sum of the squared differences between predicted values and observed prices by adjustment of the K coefficients.

In order to get a reliable assessment of the expellers values, a sample of 35 conjunctures from June 2008 up to May 2024 was gathered (quotations were taken from “La Dépêche − Le Petit Meunier”, weekly newspaper publishing agricultural commodity prices on the French and international markets). Table 4 gives the date of journal issues, the quotation of RSM and SFM and the prediction values for their respective expeller according to each method (proximal composition or nutritional values). Table 5 presents the composition of the feedstuffs considered in the computations from which Table 4 results. The Figure 2 build from these data shows the relationship between the real quotations of rapeseed and sunflower meals and the corresponding expellers.

Without surprise, the predicted values of expellers are correlated with the quotations of the solvent extracted meals and are generally superior to those of solvent meals. With predictions based on proximal values, the slope coefficients are close to 1 for both rapeseed and sunflower expellers. The values of sunflower expeller are higher than those of rapeseed expeller which can be explained by the higher oil content of the sunflower cakes. With the predictions based on nutritional values, the slopes are diverging and generally, the rapeseed expeller are showing better values than the sunflowers expellers. This is mainly explained by the lower proteins content of sunflower expellers and their lower metabolizable energy (2480 kCal/kg vs. 3130 kCal/kg) and lower protein digestibility (71.2% vs. 79.0%). In general, prediction based on proximal composition are giving better R2 coefficients than predictions based on nutritional values. It might be tempting to keep only these predictions and ignore the other but on the other hand, it seems likely that in the case of sunflower, these predictions could be overoptimistic and lead us to biased assessment. Since markets are also reacting to many other factors, it seems possible to consider that these predicted values will give us a rather good idea of the expellers prices in general trend but with rather large incertitude in individual data. An illustration of this incertitude is given by Figure 2 which represents a plot of seeds prices versus oil prices for rapeseed, sunflower and soybeans on the period 1998 to 2024. The R2 coefficient for the linear regression between sunflower seeds and oil prices is 0.79 (n = 1198). That means that only 79% of the variability of the seeds is explained by the price of the oil, 21% are due to other factor like the price of proteins, and the market position of other feedstuffs. In conclusion, it seems possible to assume that the predicted values based on proximal composition and nutritional values are giving the range within which the real prices are the most likely to be found, knowing that other factors will play a role in the determination of real prices. Nevertheless, these estimates are giving the general trends around which the real market prices will fluctuate and the linear regression given in Figure 2 can be used to assess the price of expeller-cakes in any context on the basis of the hexane extracted meals price. This value was used to perform the following computations regarding the added value of the ME process.

Quotations for meals of rapeseed (RSM) and sunflower (SFM) for 35 conjunctures, predicted value of expellers cakes (RS/SF/E) according to their proximal composition or their nutritional content, and the R2 coefficient of the adjustments.

Composition of the basket of commodities used for the determination of the predicted value of expellers cakes.

|

Fig. 2 Relationships observed between the value of the solvent extracted meals of rapeseed and sunflower and their expeller equivalent according to 2 methods of value prediction in 35 conjunctures between June 08 and May 24. |

|

Fig. 3 Linear regressions between the prices of seeds and their respective oil for: rapeseed, sunflower and soybean from 1998 to 2024 (source: la Dépêche − Le Petit Meunier, places of quotation: Rouen for rapeseed, St Nazaire for sunflower, France South-West, animal feed for soybean, Rotterdam (FOB) for the crude oils). |

|

Fig. 4 Added values comparisons between solvent extraction technology and mechanical extraction technology according to the assumptions based on observed relationships between feedstuffs prices and the composition of expeller cakes and their nutritional values. Each dot on the plots are the average values for one year based on a dataset of 574 observations. |

4 Comparison between added values of hexane extraction and mechanical extraction

Based on this assumption, and on the mater-balances given in Table 2, the added value for SE and ME can be calculated according to equation (9) and (10) for at any date where quotations for oils, seeds and meals are available using the Figure 3 linear regressions to get the value of the expellers cakes. A dataset of 574 observations gathering the quotations from 2010 to 2024 was used to produce a yearly summary from which the Figure 4 was conceived.

The cloud of dots is stretched toward the right because of the exceptionality of years 2021 to 2023. Crushing rapeseed is generally adding more value than crushing sunflower with most of dots observed between 100 and 150 €/t for rapeseed on the horizontal axis while the equivalent range is between 50 and 90 €/t for sunflower. This difference could be caused by a fiercer competition with eastern Europe crushing industry in the case of sunflower, but that remains to be evidenced. The dashed green line is the delimitation of the area where added values of ME would be superior to the added value of SE. At the exception of a few dots concerning sunflower AV based on proximal composition of expellers, the lower yields of extraction resulting from ME are leading to reduced value generated by the processing of the seeds. With rapeseed, the average reduction of added value is between 24% for the computations based on the nutritional value of the cakes and 37% when the proximal composition is used to predict their value. Regarding sunflower the range is comprised between 11% when the cake value is assed according to its proximal value and 36% if its nutritional value is considered.

The slopes of the regression lines are all less than 1, which means that the higher the crushing margins, the greater the differential between the processes. This effect is more pronounced in the case of sunflower than rapeseed if we compare the estimates based on the nutritional values of the meal. The opposite is true for predictions based on proximal compositions. These trends are explained by the higher oil content considered for the sunflower cakes and the methodology which confers more value to this oil when the price of the cakes is assessed from the proximal composition. Knowing that these cakes will be used to feed farm animals, this methodology is less reliable than the other one based on the nutritional values of the cakes.

5 Conclusion

A shift toward mechanical extraction would results in a reduction in oil yields about 10–12 points. This decrease would lead to a reduction in added value of about 30% due to a lower production of oil which is not compensated by the higher production of expeller-cake in which the residual oil has a lesser value. The variability observed in Table 1 about the oil content in expellers cakes demonstrates that better performances are possible with ME, but it is also true for worse ones. This variability is multifactorial and englobes both parameters that depends on the process control and parameters that depends upon the seeds quality. There is room for technological improvement and better performances, but it seems that ME will remain more sensitive to the variability of the oilseeds quality and there are limits to better extraction yields determined by processing cost, the oil and meal quality and the physical possibilities of the method. In general, increasing the intensity of the conditioning, for example by use of extruders, can enhance the yields of extraction but increases the cost of processing (extruder require high energy input and high maintenance costs), and high temperature can promote the oil oxidation and reduce the proteins digestibility.

For speciality markets like for organic farming or GMO-free chain values the consumer can accept the consequences of the lower competitiveness related to this way of production, but with the commodities market where concerns for environment, sustainability or reticence to genetic manipulations are not considered, mechanical extraction generates less added value than solvent extraction.

References

- Adewole DI, Rogiewicz A, Dyck B, Slominski BA. 2016. Chemical and nutritive characteristics of canola meal from Canadian processing facilities. Animal Feed Sci Technol 222: 17–30. [CrossRef] [Google Scholar]

- Association Française de Zootechnie, (2024). IO7 (French Feed Database). www.feedbase.com [Google Scholar]

- Carré P. 2021. Reinventing the oilseeds processing to extract oil while preserving the protein. OCL 28: 13. [CrossRef] [EDP Sciences] [Google Scholar]

- Carré P. 2022. New approach for the elucidation of the phenomena involved in the operation of vegetable oil extraction presses. OCL 29: 6. [CrossRef] [EDP Sciences] [Google Scholar]

- Carré P, Quinsac A, Citeau M, Fine F. 2015. A re-examination of the technical feasibility and economic viability of rapeseed dehulling. OCL 22: D304. [CrossRef] [EDP Sciences] [Google Scholar]

- Chen J, Wedekind K, Escobar J, Vazquez-Añón M. 2020. Trypsin inhibitor and urease activity of soybean meal products from different countries and impact of trypsin inhibitor on ileal amino acid digestibility in pig. J Am Oil Chem Soc 97: 1151–1163. [CrossRef] [Google Scholar]

- Cheng MH, Rosentrater KA. 2017. Profitability analysis of soybean oil processes. Bioengineering 4: 83. [CrossRef] [PubMed] [Google Scholar]

- Cheng MH, Rosentrater KA. 2019. Techno-economic analysis of extruding-expelling of soybeans to produce oil and meal. Agriculture 9: 87. [CrossRef] [Google Scholar]

- Cheng MH, Dien BS, Singh V. 2019. Economics of plant oil recovery: a review. Biocatal Agric Biotechnol 18: 101056. [CrossRef] [Google Scholar]

- Cheng MH, Sekhon JJ, Rosentrater KA, Wang T, Jung S, Johnson LA. 2018. Environmental impact assessment of soybean oil production: extruding-expelling process, hexane extraction and aqueous extraction. Food Bioprod Process 108: 58–68. [CrossRef] [Google Scholar]

- Feedtables. 2024 [database by INRAE-CIRAD-AFZ]. www.feedtables.com. Last consult, June 2024 [Google Scholar]

- Fisher WD, Schruben LW. 1953. Linear programming applied to feed-mixing under different price conditions. J Farm Econ 35: 471–483. [CrossRef] [Google Scholar]

- La Dépêche − Le Petit Meunier (1998-2024). [weekly publication]. www.reussir/ladepeche. [Google Scholar]

- Laisney J. 1984. L’huilerie moderne“ Art et techniques”. ISBN 2-904157-00–3 [Google Scholar]

- Leming R, Lember A. 2005. Chemical composition of expeller-extracted and cold-pressed rapeseed cake. Agraarteadus 16: 96–109. [Google Scholar]

- Maciel G, Wagner JR, Juan NA, San Martino S, Bartosik R. 2020. Assessment of the main sources of variability of soybean (Glycine max) expeller composition and quality: a field study. AgricEngInt: CIGR J 22. [Google Scholar]

- NANP: National Animal Nutrition Program database. https://animalnutrition.org/feed-composition-database. Last consult: June 2023 [Google Scholar]

- NRC Tables. 2001. https://fr.scribd.com/document/501092649/Table-Nutrient-NRC-2001. Last consult June 2024 [Google Scholar]

- Pearson JW. 1919. The seed-crushing Industry. J Roy Soc Arts 68: 50–62. [Google Scholar]

- Pesti GM, Miller BR. 1993. Animal feed formulation: economic and computer applications. Springer Science & Business Media. [Google Scholar]

- Savoire R, Lanoisellé JL, Vorobiev E. 2013. Mechanical continuous oil expression from oilseeds a review. Food Bioproc Technol 6: 1–16. [CrossRef] [Google Scholar]

- Sprague J, Mailer RJ. 2008. Canola Meal Value Chain Quality Improvement. A final report prepared for AOF and Pork CRC. https://www.porkcrc.com.au/1B-106_Final_Project_Report.pdf [Google Scholar]

- St-Pierre NR. 2003. Pricing feed ingredients on the basis of market values of nutrients. In Texas Animal Nutrition Conference Proceedings (pp. 21–28). [Google Scholar]

- St-Pierre NR, Glamocic D. 2000. Estimating unit costs of nutrients from market prices of feedstuffs. J Dairy Sci 83: 1402–1411. [CrossRef] [PubMed] [Google Scholar]

- Tranchefort J. 1974. La regression, Application à l’Agronomie. Institut technique des Céréales et des Fourrages (ITCF), 178p. [Google Scholar]

- Tröster MF, Heinz M, Durst L. 2023. Determining the value of novel feedstuffs in imperfect markets, taking Lupinus albus as an example. Agriculture 13: 867. [CrossRef] [Google Scholar]

- Wolff JP. 1983. Residual hexane in meals. J Am Oil Chem Soc 60: 220–223. [CrossRef] [Google Scholar]

Cite this article as: Carré P. 2024. Economics of oilseed crushing: assessing the impact of solvent-free processing on added value. OCL 31: 27.

All Tables

Average water and oil content in rapeseed and sunflower according to the Terres Inovia survey from 2014 to 2022, Feedbase/IO7 for solvent extracted meals and expeller cakes (not for the Seeds).

Matter balance for the processing of 100 kg of seeds according to solvent extraction and mechanical extraction.

Quotations for meals of rapeseed (RSM) and sunflower (SFM) for 35 conjunctures, predicted value of expellers cakes (RS/SF/E) according to their proximal composition or their nutritional content, and the R2 coefficient of the adjustments.

Composition of the basket of commodities used for the determination of the predicted value of expellers cakes.

All Figures

|

Fig. 1 Cumulative capacity of crushing units operating solely by mechanical extraction in France. |

| In the text | |

|

Fig. 2 Relationships observed between the value of the solvent extracted meals of rapeseed and sunflower and their expeller equivalent according to 2 methods of value prediction in 35 conjunctures between June 08 and May 24. |

| In the text | |

|

Fig. 3 Linear regressions between the prices of seeds and their respective oil for: rapeseed, sunflower and soybean from 1998 to 2024 (source: la Dépêche − Le Petit Meunier, places of quotation: Rouen for rapeseed, St Nazaire for sunflower, France South-West, animal feed for soybean, Rotterdam (FOB) for the crude oils). |

| In the text | |

|

Fig. 4 Added values comparisons between solvent extraction technology and mechanical extraction technology according to the assumptions based on observed relationships between feedstuffs prices and the composition of expeller cakes and their nutritional values. Each dot on the plots are the average values for one year based on a dataset of 574 observations. |

| In the text | |

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.