| Issue |

OCL

Volume 32, 2025

|

|

|---|---|---|

| Article Number | 21 | |

| Number of page(s) | 23 | |

| Section | Quality - Food safety | |

| DOI | https://doi.org/10.1051/ocl/2025017 | |

| Published online | 09 July 2025 | |

Research Article

Utilizing phenolic-enriched sunflower Oleogels and Emulgels as fat replacers: impact on burger oxidative stability, texture, and sensory attributes

Utilisation d’oléogels et d’émulgels au tournesol enrichis en composés phénoliques comme substituts de matières grasses : impact sur la stabilité oxydative, la texture et les propriétés sensorielles de burgers

1

Department of Sport health, College of sport Sciencess and Physical Activity, Princess Nourah bint Abdulrahman University, P.O. Box 84428, Riyadh 11671, Saudi Arabia

2

Agricultural Engineering Research Institute, Agricultural Research Center, Dokki, Giza 12611, Egypt

3

Home Economics Department, Faculty of Specific Education, Alexandria University, Alexandria, Egypt

4

Agricultural Research Center, Food Technology Research Institute, Giza 12611, Egypt

5

Home Economics Department, Faculty of Specific Education, Kafrelsheikh University, Kafrelsheikh, Egypt

* Corresponding author: mohamedabdelbasetsalama@gmail.com

Received:

13

December

2024

Accepted:

19

May

2025

This study aimed to develop and characterize sunflower oil–beeswax oleogels and emulgels enriched with onion peel phenolic extract (EMEX) as fat replacers in food products. High-performance liquid chromatography (HPLC) analysis identified quercetin (432.15 μg/g) and kaempferol (295.23 μg/g) as the predominant phenolic compounds in the onion peel extract. The physical properties of sunflower oil oleogels and emulgels were assessed, including gelation time, oil binding capacity (OBC), firmness, and melting temperature. The OBC slightly decreased from 95.17% in OLEO to 87.45% in EMEX, while firmness decreased from 4.26 N to 3.83 N. The incorporation of EMEX enhanced the total phenolic content (5.49 mg GAE/g) and antioxidant activity (DPPH, 38.84%). Hamburgers formulated with these structured lipids underwent sensory evaluation, which revealed improved appearance (8.35) and juiciness (9.0) for the EMEX-based samples. Storage stability at 4 °C for 14 days demonstrated that burgers containing oleogels and emulgels exhibited better moisture retention, reduced firmness loss, and delayed lipid oxidation compared to the control. The inclusion of phenolic-rich emulgels further improved oxidative stability, as indicated by lower peroxide values and TBARS levels. These findings highlight the potential of oleogels and emulgels, particularly those enriched with natural antioxidants, as viable fat replacers that enhance both quality and shelf life in refrigerated meat products.

Résumé

Cette étude visait à développer et à caractériser des oléogels et des émulgels à base d’huile de tournesol et de cire d’abeille, enrichis avec un extrait phénolique de pelures d’oignon (EMEX), en tant que substituts de matières grasses dans les produits alimentaires. L’analyse par chromatographie en phase liquide à haute performance (HPLC) a identifié la quercétine (432,15 µg/g) et le kaempférol (295,23 µg/g) comme les principaux composés phénoliques présents dans l’extrait de pelures d’oignon. Les propriétés physiques des oléogels et émulgels à base d’huile de tournesol ont été évaluées, notamment le temps de gélification, la capacité de rétention d’huile (OBC), la fermeté et la température de fusion. L’OBC a légèrement diminué, passant de 95,17 % dans l’oléogel (OLEO) à 87,45 % dans l’EMEX, tandis que la fermeté a baissé de 4,26 N à 3,83 N. L’incorporation de l’EMEX a permis d’augmenter la teneur totale en composés phénoliques (5,49 mg GAE/g) et l’activité antioxydante (DPPH, 38,84 %). Des hamburgers formulés avec ces lipides structurés ont été soumis à une évaluation sensorielle, qui a révélé une amélioration de l’apparence (8,35) et de la jutosité (9,0) pour les échantillons à base d’EMEX. Un stockage à 4 °C pendant 14 jours a montré que les burgers contenant des oléogels et émulgels conservaient mieux l’humidité, perdaient moins de fermeté et subissaient une oxydation lipidique retardée par rapport au témoin. L’ajout d’émulgels riches en composés phénoliques a encore amélioré la stabilité oxydative, comme l’indiquent les valeurs plus faibles de peroxydes et de TBARS. Ces résultats soulignent le potentiel des oléogels et émulgels, en particulier ceux enrichis en antioxydants naturels, comme substituts de matières grasses efficaces améliorant à la fois la qualité et la durée de conservation des produits carnés réfrigérés.

Key words: Sunflower oil-based oleogel / Emulgel / burger quality / fat replacer / oxidative stability

Mots clés : Oléogel / huile de tournesol / émulgel / burger / substitut de matière grasse / stabilité oxydative

Publisher note: Le résumé et les mots-clés en français ont été ajoutés le 25/07/2025. French abstract and keywords have been added the 25/07/2025.

© H.A. Alamer et al., Published by EDP Sciences, 2025

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Highlights

Emulgels enriched with onion phenolic extract showed a notable increase in total phenolic content and antioxidant activity which improved oxidative stability.

The incorporation of oleogels and emulgels in burger formulations reduced hardness and cohesiveness while increasing springiness and chewiness. Phenolic extract-enriched emulgel further enhanced the sensory attributes, particularly in terms of flavor and juiciness, without compromising texture.

Both oleogel and emulgel-based burgers exhibited lower peroxide and TBARS values compared to the control. The phenolic-enriched emulgel (EMEX) demonstrated the greatest reduction in lipid oxidation, indicating its potential as a fat replacer with antioxidant benefits in meat products.

1 Introduction

In recent years, food systems have undergone significant changes due to innovations in food processing technologies. The growing pace of modern life has led to an increased demand for convenient and cost-effective food products. Consequently, traditional diets centered around whole or minimally processed foods are being increasingly replaced by industrialized and pre-packaged food options in today’s society (Poti et al., 2017).

Saturated fats are widely used in many processed foods because of technological reasons. These fats play a crucial role in providing desirable sensory attributes, such as texture, mouthfeel, and flavor, making their replacement difficult without compromising key qualities and overall eating satisfaction. Consequently, the intake of essential fatty acids and antioxidants, commonly found in traditional diets, has been replaced by unhealthy fats. This shift is strongly associated with various health problems (Martins et al., 2020).

The search for healthier fat alternatives is not new; the hydrogenation process was developed in the early 20th century as a way to replace saturated fats (animal sources) and reduce cholesterol by using healthier oils (vegetable and marine), which are rich in beneficial polyunsaturated fatty acids. This alters the oils’ saturation levels, giving them manufacturing benefits (firmness and plasticity) (Remig et al., 2010). However, despite these technological advantages, hydrogenation introduced trans fatty acids (TFAs), which are now well recognized for their adverse health effects, including increased cardiovascular risk. This has driven regulatory bans and a strong push toward developing safer alternatives.

The liquid form of vegetable oils restricts their use in certain applications, as they lack the same characteristics as solid fats (Marangoni and Garti, 2018). In light of this and within government initiatives aimed at eliminating unhealthy fats from the market, the food industry has witnessed the emergence of new oil structuring techniques, with oleogels leading the scientific exploration. Oil structuring relies on the creation of a gelator network that forms a stable, thermo-reversible viscoelastic structure without altering the oil’s chemical composition. Conventional hydrogenation, previously used to solidify oils, has been associated with the formation of trans fatty acids (TFAs), which are linked to an increased risk of cardiovascular diseases, inflammation, and other metabolic disorders (Souad, 2024). Additionally, partial hydrogenation can lead to changes in flavor and nutritional quality, prompting regulatory bans or restrictions in many countries (Bhandari et al., 2020). Unlike hydrogenation, oleogels offer a promising method for structuring PUFA-rich oils while preserving their nutritional benefits (Martins et al., 2020). Consumer acceptance of oleogels hinges on their ability to replicate the properties of solid fats. Additionally, oleogels can be customized for specific applications, with structural and textural attributes playing a crucial role. Beyond substituting unhealthy fats with beneficial oils, oleogels can be further enhanced by incorporating bioactive compounds into their formulation. This added functionality not only boosts nutritional value but also enhances product appeal by improving stability and extending shelf life (Pinto et al., 2021). Recent research has also highlighted the potential of oleogels to act as carriers for bioactive compounds, thus enabling the development of multifunctional foods with enhanced health benefits.

Despite the growing interest in oleogels, there remains a significant knowledge gap in fully understanding how to optimize their structural and functional properties, particularly in terms of their ability to replicate the properties of solid fats while incorporating bioactive compounds to enhance their health-promoting properties. A key challenge lies in balancing structural integrity with bioactive loading, especially when applying these systems in complex food matrices such as meat products.

Gels are categorized based on the type of liquid phase they contain, such as hydrogels, emulgels, and organogels. When an aqueous solution forms a gel, it is referred to as a hydrogel. If a gel is created from a biphasic mixture, it is termed an emulgel. When an organic solvent is used to form the gel, it is called an organogel (Martins et al., 2018). To differentiate an edible liquid oil gel, the term of oleogel was preferred within the organogel category (Marangoni and Garti, 2018). Emulgels, combining both emulsification and gelation, offer additional flexibility by enabling the incorporation of aqueous and oil phases simultaneously, widening their potential applications in food systems.

Unsaturated fatty acids typically have melting points below 0 °C due to their chemical structure, but by transforming these fatty acids into oleogels using gelators, they can be made to form semi-solid gels at room temperature (Hyatt et al., 2023; Willett and Akoh, 2019). Oleogels can inhibit photooxidation and free radical-induced peroxidation reactions by immobilizing molecules and decreasing molecular collisions (Tian and Acevedo, 2020).

Another less commonly utilized processing technique examined in this study is the creation of emulsion gels (emulgels). While experimentation with emulgels presents unique challenges due to the presence of water in the sample matrix, they offer the same advantages as oleogels but in an emulsion format. These gels provide additional potential for application in food products, cosmetics, and pharmaceuticals (Sato et al., 2014). Emulgels are especially promising for improving water-holding capacity and delivering both lipophilic and hydrophilic bioactive compounds.

Phenolic compounds derived from onion peels offer a promising approach to enhancing the functional and nutritional properties of food systems. Onion peels, often regarded as agricultural waste, are an abundant and sustainable source of bioactive compounds, particularly quercetin and kaempferol, which are recognized for their potent antioxidant activities (Benito-Román et al., 2020; Celano et al., 2021). These phenolics play a crucial role in scavenging free radicals, delaying lipid oxidation, and improving the oxidative stability of food products (Silva et al., 2022). Incorporating phenolic extracts from onion peels into food formulations not only reduces food waste but also aligns with the growing demand for natural and health-promoting additives (Stoica et al., 2023). Moreover, these compounds have demonstrated effectiveness in enhancing sensory attributes such as flavor and appearance while extending product shelf life (Paesa et al., 2022). Utilizing phenolics from onion peels represents an innovative and eco-friendly solution to developing functional ingredients, offering both environmental benefits and improved product quality.

Meat and meat products play a crucial role in diets worldwide, offering substantial protein content and high nutritional value, but their levels of saturated and trans fatty acids can pose health risks. A diet high in saturated fats is associated with an increased likelihood of various health issues. As a result, the meat industry is under pressure to create healthier products alternatives with an enhanced fatty acid profile to safeguard consumer health. One solution lies in the technological improvement of the fatty acid profile by substituting animal fats in meat products with healthier fat options (Manzoor et al., 2022). However, the incorporation of healthier fats, particularly in structured systems like oleogels and emulgels, requires careful evaluation to ensure that desirable texture, mouthfeel, and stability are maintained in the final product.

The aim of this study is to bridge the gap in knowledge by exploring the use of oleogels and emulgels as structured systems to replace unhealthy fats in food products while incorporating antioxidant-rich phenolic compounds from onion peels. This innovative approach not only addresses health concerns by providing healthier fat alternatives but also contributes to reducing food waste, offering a sustainable solution to the growing demand for functional, eco-friendly food ingredients. The study further evaluates the impact of these structured systems on the physicochemical, textural, and thermal properties of the formulations, aiming to provide comprehensive insights into their practical applications in meat product development.

2 Materials and methods

2.1 Materials

Sunflower oil was sourced from Tanta Company of Oils and Soaps, located in Tanta city, Egypt. Onions were obtained from a local market in Kafrelsheikh, Egypt. Beeswax was supplied by Kahlwax Co. (Kalh GmbH & Co., Trittau, Germany). Tween 80 (polysorbate 80; analytical grade, ≥99% purity) was purchased from Sigma-Aldrich (St. Louis, MO, USA). All chemicals, solvents, and standards used were of analytical grade.

2.2 Methods

2.2.1 Phenolic compounds extraction from onion peels

The onion peels were removed and placed in an air oven (Marconi, MA-035/100, Piracicaba, Brazil) at 60 °C for 8 h. Thirty grams of the dried peels were ground using a mill (IKA, A11 BS000, Germany), and the powder was extracted twice using 300 mL of distilled water at room temperature (25 °C) over 48 h. To minimize the degradation of light-sensitive compounds, the extraction was carried out in the dark by covering the containers with aluminum foil. The extracts were filtered, and the filtrates were concentrated with the help of a rotary evaporator (Alshehri et al., 2024). The remaining residues were frozen at −80 °C and later subjected to lyophilization at −40 °C for 48 h to produce a lyophilized powder. The resulting powder was then stored at −20 °C until further use.

2.2.2 Phenolic compounds determination

The quantification of phenolic compounds in onion extracts was carried out using HPLC-DAD. For this analysis, 30 mg of freeze-dried extract was dissolved in 350 μL of methanol and filtered through PTFE syringe filter (0.45 μm). The analysis was performed using HPLC equipped with a photodiode array detector (Waters Div., Milford, MA, USA) and a reversed-phase LC column (250 mm × 4.6 mm, 5 μm) (Torrance, CA, USA) was utilized at 30 °C. The mobile phases consisted of (A) formic acid (0.5%) in water and (B) formic acid (0.5%) in acetonitrile with stable flow rate (0.8 mL/min), and the injection volume was 10 μL (Paesa et al., 2022).

2.2.3 Development and characterization of the oleogels systems

2.2.3.1 Oleogel and emulgels preparation

To prepare the oleogel (OLEO), 9% of beeswax was melted in a glass beaker at 80 °C for 7 min. Sunflower oil was then added, and the mixture was heated to 80 °C for 20 min while stirring at 700 rpm using a magnetic stirrer (Salama et al., 2024). The concentration of 9% beeswax was chosen based on previous studies and preliminary experiments, which indicated that this ratio provides a stable and firm gel structure suitable for food applications, balancing firmness with desirable spreadability (Alshehri et al., 2025; Salama et al., 2024). The oleogel was then allowed to cool to room temperature and stored at 4 °C in the refrigerator until analysis.

For the emulgel (EM), the previously melted 9% of beeswax was combined with the oil. Tween 80 (0.5 g) was dissolved in water (10%), and the two mixtures were emulsified together using an Ultra-Turrax T25 homogenizer (IKA- Staufen, Germany) at 16,000 rpm for 5 minutes. Emulsification was carried out at room temperature (∼25 °C). The flask was covered to prevent water evaporation during the emulsification process.

For the emulgel with phenolic extract (EMEX), onion phenolic lyophilized extract (0.25 g) was mixed with the Tween 80-water solution. This mixture was then emulsified with the oil-beeswax mixture using the homogenizer at 16,000 rpm for 5 minutes (Keskin Uslu and Yılmaz, 2021). The resulting emulsions were left at room temperature overnight to allow for gelation and were then stored at 4 °C in the refrigerator until analysis (Fig. 1A)

|

Fig. 1 (A1) Sunflower oil, (A2) Oleogel, (A3) Emulgel, (A4) Emulgel with phenolic onion extract; (B1) Control burger, (B2) Oleogel burger, (B3) Emulgel burger, (B4) Emulgel with phenolic onion extract burger. |

2.2.3.2 Gelation time

The samples in glass tubes were fully melted in a water bath at 90 °C and maintained for 2 h to allow for isothermal setting. Afterward, the tubes were removed from the water bath and brought to room temperature, at which point a timer was started. The gelation time was recorded when the tubes were tilted 90° and no flow of the organogel was observed (Yılmaz and Öğütcü, 2015).

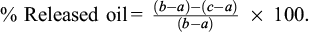

2.2.3.3 Oil binding capacity (OBC)

1 mL of sample was transferred into a pre-weighed Eppendorf tube (a) and then placed in a refrigerator at 4 °C for 1 h. After refrigeration, the tube was weighed again (b). The tube was then centrifuged at 9167g for 15 min at room temperature (25 °C). Following centrifugation, the tube was inverted onto a paper cloth to drain any excess liquid oil. After the drainage process, the tube was weighed once more (c) (Yılmaz and Öğütcü, 2015). OBC values were subsequently calculated using the specified equation.

% Released oil =

% OBC = 100 – % Released oil

2.2.3.4 Colors determination

Color measurements were taken using a Minolta CR-400 colorimeter (Konica Minolta Sensing, Osaka, Japan) following CIE standards, and the L, a*, and b* values were documented.

2.2.3.5 The centrifuge stability test

The centrifuge stability test was performed by subjecting a 5 g sample in tubes to a centrifugation force of 1300× g for 15 min at room temperature. The stability of the gel was then assessed through visual inspection (Yilmaz and Demirci, 2021).

2.2.3.6 Melting point

In summary, 7 g of molten sample were placed into glass tubes. The tubes were then immersed in a precision water bath set to 38 °C. The water bath, equipped with a temperature control system and digital thermometer, was used to increase the temperature at a constant rate of 1 °C every 3 min. The temperature was carefully monitored and manually adjusted to maintain the desired heating rate until the samples were completely melted and became transparent liquids (Zampouni et al., 2022).

2.2.3.7 Firmness

The firmness of the gels was assessed using a Texture Analyser (CT3 4500, Brookfield, USA) at room temperature. The samples (30 g) were stored in a 50 mL glass beaker in a refrigerator at 5 °C for 24 h to simulate typical storage conditions and ensure uniform cooling and stabilization of the gels. Before testing, each sample was allowed to equilibrate to room temperature for approximately 10 minutes to prevent temperature fluctuation during the measurement. For the test, each sample was removed individually, and the TA4/1000 probe, with a diameter of 1 cm, was used. The firmness was determined by recording the maximum penetration force (Öğütcü and Yılmaz, 2015).

2.2.3.8 Phenolic extraction from oleogel and emulgels

In this extraction procedure, 50 g of different samples were processed through a glass column packed with silica gel (60-Å pore diameter). The column is initially conditioned with a hexane and methanol (1:1 V:V) mixture and subsequently washed with hexane and ethyl acetate (9:1 V:V) to prepare it for sample introduction. The oil sample, dissolved in hexane, is introduced into the column, where the phenolic fraction is extracted into methanol. After passing through the column, the extract is collected and the solvent is removed under vacuum at 40 °C to yield a concentrated extract. These extracts are stored at −20 °C after flushing with nitrogen to prevent oxidation (Steel et al., 2005).

2.2.3.9 Total phenolic content (TPC)

100 μL of samples (oleogel (OLEO), emulgel (EM), and emulgel with phenolic extract (EMEX)) and standards (gallic acid) were added to 750 μL of Folin’s reagent and 750 μL of 7% Na2CO3 and incubated for 45 min at room temperature in dark. The absorbance was then read at 765 nm using spectrophotometer (Analytik Jena Specord 250). The concentration was measured using gallic acid as standard and the results were expressed as mL gallic acid equivalents (GAE)/g sample (Attard, 2013).

2.2.3.10 Antioxidant activity using DPPH assay

0.1 mL of samples (oleogel (OLEO), emulgel (EM), and emulgel with phenolic extract (EMEX)) were mixture with 0.2 mM DPPH solution (2 mL). A control was also performed simultaneously. In the dark, the samples were kept for 30 min. After that, at 517 nm the absorbance was measured using a spectrophotometer (Analytik Jena Specord 250) (Boly et al., 2016). The DPPH radical scavenging activity was determined using the provided equation.

DPPH antioxidant activity (%) = ((control ab − sample ab)/(control ab)) × 100

where: control ab represented the absorbance of the DPPH working solution without the sample, and sample ab corresponded to the absorbance of the DPPH working solution when mixed with samples.

2.2.3.11 Fatty acids measurement

A drop of the oil sample was dissolved in 1 mL of n-heptane. Next, 50 mg of sodium methylate (Merck, Darmstadt, Germany) was added to the tube, which was then agitated for 60 s at room temperature. After adding 100 mL of water, the tube was centrifuged at 3000×g for 5 min, and the lower aqueous phase was carefully removed. Subsequently, 50 mL of HCl (1 mol with methyl orange; Merck, Darmstadt, Germany) was added, and the lower phase was eliminated after brief mixing. Sodium hydrogen sulphate (20 mg) (monohydrate, extra pure; Merck, Darmstadt, Germany) was added to the tube, and the sample was centrifuged at 3000 g for 5 min. A gas chromatograph (GC) with a CP-Sil 88 capillary column (ID 0.25 mm, 100 m long, 0.2 mm film thickness) was used to inject the top phase (n-heptane) that had been collected in a vial. The GC was manufactured by Agilent Technologies Sales & Services GmbH & Co. KG in Waldbronn, Germany and was designated as HP5890. The temperature program started at 155 °C and increased to 220 °C at a rate of 1.5 °C/min, with an injector temperature of 250 °C, a 10-minute isotherm at 220 °C, and a detector temperature of 250 °C. Hydrogen was used as the carrier gas at 36 cm/s, with a split ratio of 1:50. The flow rates of the detector gases were 30 mL/min for hydrogen, 300 mL/min for air, and 30 mL/min for nitrogen. Under 1 milliliter of fluid was injected manually. Fatty acid methyl esters (FAME) percentages were computed as a weight percent using direct internal normalization, and peak areas were estimated using integration software (Salama et al., 2020).

2.2.3.12 Microstructural analysis by scanning electron microscopy (SEM) and atomic force microscopy (AFM)

The microstructure of the oleogel and bigel samples was characterized using both scanning electron microscopy (SEM) and atomic force microscopy (AFM).

For SEM analysis, oleogel samples were rapidly frozen to stabilize the gel network and minimize oil migration. The frozen samples were carefully mounted onto aluminum stubs and immediately coated with a 10 nm gold layer using a Sputter Coater 108 Auto (Cressington Scientific Instruments, Watford, UK) to enhance conductivity. Imaging was conducted using an EVO 40XVP SEM (Carl Zeiss, Milan, Italy), operated under high-vacuum conditions at room temperature with an accelerating voltage of 20 kV. Care was taken to minimize beam exposure time to reduce the risk of thermal damage or structural changes. Images were captured and processed using SmartSEM v. 5.09 software (Carl Zeiss, Milan, Italy).

For AFM analysis, the surface topography of freshly prepared oleogel films was examined using a NanoScope MultiMode AFM (Veeco Metrology, Inc., Santa Barbara, USA). Samples were analyzed in tapping mode to minimize tip-sample interaction forces, thus reducing potential deformation of the soft gel matrix. The instrument was equipped with a standard scanning probe microscopy (SPM) probe, and images were obtained at room temperature shortly after sample preparation to preserve the native microstructure (Abdin et al., 2024).

2.2.3.13 Differential scanning calorimetry (DSC)

The thermal properties, specifically the melting behavior of the oleogel and emulgel samples, were analyzed using differential scanning calorimetry (DSC 200, NETZSCH, Germany) following the method described by Tabibazar et al., 2020 with minor modifications. In summary, 2–4 mg of the sample was placed in an aluminum pan, sealed, and heated from 30 to 200 °C at a rate of 5 °C/min under a nitrogen flow of 20 mL/min.

2.2.3.14 Viscosity of oleogel and emulgels

The viscosity of the samples (gel A and gel B) was determined using a Viscometer (LR Lamy Rheology instrument). The samples were first melted in a water bath at 80 °C. Once fully melted, the oleogel samples were transferred to the viscometer’s sample cell, and their viscosity was recorded as the temperature gradually decreased from 80 °C to 20 °C at a rate of approximately 1 °C per minute. The cooling rate was controlled using the viscometer’s integrated temperature control system, which was programmed to achieve a linear cooling profile. The viscosity values were then plotted against the corresponding temperatures (Sahu et al., 2020).

2.2.4 Chemical properties of oleogel systems and burger

2.2.4.1 Free fatty acid and peroxide value

Free fatty acid and peroxide value were determined according to (AOCS, 2017).

2.2.4.2 Sensory evaluation

The sensory evaluation of the oleogel and burger samples were done by 20 panelists from the Staff of Food Technology Research Institute, Egypt. The acceptance attributes for oleogels were appearance, spreadability, taste, odor and overall acceptability. While for burger samples the attributes were color, odor, flavor, appearance, juiciness, firmness and overall acceptability (Meilgaard et al., 1999).

2.2.5 Development and characterization of burger samples

2.2.5.1 Burger preparation and storage

Lean beef meat was obtained from a local market, Kafrelsheikh, Egypt. Three different hamburger batches were manufactured:

Control burger: with 90% of lean beef and 10% of bovine back fat.

OLEO burger: with 90% of lean beef and 10% of oleogel.

EM burger: with 90% of lean beef and 10% of emulgel.

EMEX burger: with 90% of lean beef and 10% of emulgel with onion peels pheolic extract.

The various ingredients of the burger were individually ground using a domestic MOULINEX HV8 PRO ME686832 meat grinder fitted with a medium coarse grinding plate (4 mm). The ground components were then combined with marine salt (0.5%). Portions of 200 g from each mixture were manually shaped into round patties with a diameter of 9.5 cm and pressed to a height of 2 cm. The burgers were stored at −20 °C in polypropylene bags in triplicate for 14 days. At each storage time point, the samples were analyzed accordingly (Fig. 1B).

2.2.5.2 Texture analyses

A texture analyzer (Instron 1011, Norwood, MA, USA), fitted with a 50-N load cell, was used to assess the texture of the samples. Glass tubes with an internal diameter of 2 cm were filled with 15 mL of the samples and stored at 4 °C. The penetration force was determined by plunging a cylindrical probe into the samples at a penetration speed of 100 mm/min to a depth of 2 cm. The maximum force recorded was reported as the penetration force (N) (Hayes et al., 2005).

2.2.5.3 Weight loss (%)

The weight loss of burger samples was determined by measuring the change in weight over a 14-day storage period at 4 °C. Initially, the raw burger samples were weighed using an analytical balance (accurate to 0.01 g) before storage. The samples were then stored in a refrigerator at 4 °C for 14 days. At each time point (e.g., Days 0, 7, and 14), the burger samples were removed from the refrigerator, allowed to reach room temperature, and weighed again to determine the final weight. The weight loss was calculated as the percentage of weight reduction using the formula:

Weight loss (%) = ((Initial weight − Final weight)/Initial weight) × 100.

2.2.5.4 Cooking loss (CL)

Cooking loss of samples was calculated as described by Erdogdu et al., (2007) following the formula:

Cooking Loss (CL %) = (Mi − Mf)/Mi × 100

Where: Mi = Initial mass of the raw sample in gram, Mf = Final mass of the cooked sample in grams.

2.2.5.5 Water holding capacity

Water holding capacity was determined as described by Jia et al. (2018) with some modifications. In summary, each sample (1 g) mixed with 10 mL of distilled water in centrifuge tube, vortexed for 5 minutes and then centrifuged for 30 min at approximately 2795×g. The removal of water layer was done then, the weights (wt.) of centrifuge tubes were measured and the following equation was used to calculate WHC:

% WHC = [(wt. of tube after decanting (g) − wt. of dry tube (g)) − wt. of total sample (g)] × 100/ wt. of total sample (g).

2.2.5.6 pH measurement

The pH of the burger samples was measured using a pH meter (MP512-03, Hangzhou Tuqi Instrument Co., Ltd, China). A mixture was prepared by blending 5 g of the sample with 45 mL of distilled water using an Ultra-Turrax T25 homogenizer (IKA-Labortechnik, Staufen, Germany) for 30 s at 3000 rpm. Prior to sample analysis, the pH meter was calibrated using buffer solutions at pH 4.0 and pH 6.8 (at 20 °C) following the method outlined by Holman et al. (2017).

2.2.5.7 TBARS determination

Lipid oxidation in the burger samples during different stages of frozen storage was evaluated by measuring TBARS, following the method described by Maraschiello et al. (1999) with minor modifications. In short, 5 g of burger samples were soaked in 20 mL of distilled water and homogenized using an Ultra-Turrax T25 (IKA-Labortechnik, Staufen, Germany) for 10 seconds at 13,500 rpm. The homogenized mixture was combined with 50 mL of cold 7.5% trichloroacetic acid (TCA) solution containing 1 g of EDTA and stirred gently at 50 °C for 30 min. The mixture was then filtered, and the supernatant was collected. A 5 mL aliquot of the supernatant was mixed with 5 mL of 0.02 M 2-thiobarbituric acid (TBA), and the mixture was incubated in a screw-capped tube in a 90 °C water bath for 30 min. TBARS values were determined in triplicate using a spectrophotometer (Analytik Jena Specord 250) at 532 nm against a blank. Calibration curves, based on 1,1,3,3-tetraethoxypropane, were created using the same TBA procedure for sample analysis. Results were expressed in μg MDA/kg of the sample, with all measurements performed in triplicate.

2.2.6 Statistical analysis

The data were analyzed using SPSS software (16.0) to assess variance through the one-way analysis of variance (ANOVA) method. Samples were computed based on three repetitions.

3 Results and discussion

3.1 Phenolic compounds of onion peels extract

The HPLC analysis of the onion peel water extract revealed a rich profile of phenolic compounds, with quercetin (432.15 μg/g) and kaempferol (295.23 μg/g) being the most abundant (Tab. 1). These results allowed us to verify that onion peel extract is a valuable source of bioactive compounds, consistent with previous studies, such as (Benito-Román et al., 2020; Paesa et al., 2022), which also identified quercetin as a dominant flavonoid in onion peels. Although it is well-known that onion peels contain these compounds, the high levels of quercetin and other significant compounds, including gallic acid (154.87 μg/g), caffeic acid (90.45 μg/g), and ferulic acid (72.33 μg/g), contribute to the extract’s potent antioxidant capacity, aligning with findings by Celano et al. (2021). The presence of these phenolics enhances the extract’s potential use as a natural antioxidant in food preservation and nutraceuticals. This study confirms the viability of onion peels, traditionally considered waste, as a sustainable source for bioactive compound extraction, offering both environmental and economic benefits (Kumar et al., 2022). Our findings further highlight the significant potential of onion peel extracts as a functional ingredient in food systems, particularly for antioxidant applications.

Phenolic compounds identified in onion peel water extract (μg/g).

3.2 Development and characterization of the oleogels systems

3.2.1 Physical properties of sunflower oil-beeswax oleogel and emulgel

The data presented in Figure 2A provide insights into the physico-chemical properties of the sunflower oil, oleogel, and emulgel samples. Gelation time reflects how quickly the gel network forms, impacting the texture and stability of the final product. In this case, the addition of beeswax to create the sunflower oleogel resulted in a gelation time of 7.31 min, consistent with studies showing that beeswax, as a structuring agent, forms a stable network by solidifying the oil phase (Salama et al., 2024). Beeswax has been widely recognized for its gelation properties, even at low concentrations, as minimal as 0.5 wt%, which results in a well-structured network with excellent oil-binding capabilities (Abdallah et al., 2000). Patel et al. (2014) also reported that oleogels structured with beeswax formed gel networks rapidly due to the crystallization of wax components, leading to quick gelation times.

The gelation time for the emulgel (EM) was slightly longer (8.72 min), which could be attributed to the additional components in the emulsion, such as water and emulsifying agents. The presence of both an oil phase and a water phase in the emulgel slows down the gelation process compared to the simpler oleogel system, as more interactions between phases need to stabilize before a gel network forms. This result is consistent with existing literature, which suggests that emulgels typically exhibit longer gelation times compared to oleogels due to the complexity of their multi-phase systems (Keskin Uslu and Yılmaz, 2021). When phenolic extract was added to the emulgel (EMEX), the gelation time increased slightly further to 8.99 min. Our findings suggest that the incorporation of phenolic compounds into the emulgel system could affect the gelation dynamics, potentially by interacting with the emulsifying agents or the oil droplets, creating a more intricate network. This slight increase in gelation time indicates that the phenolics play a role in modifying the physical properties of the system, although this effect is less pronounced than in other systems.

The gelling mechanism of beeswax is related to the arrangement of n-alkanes or wax esters into microcrystalline platelets, which aggregate to form a three-dimensional network that effectively traps the liquid oil (Martini et al., 2015). The ability of oleogels to retain oil within their matrix provides insights into their stability and the efficiency of the crystal network’s formation (Okuro et al., 2018), offering potential applications in food products (Doan et al., 2016).

Oil Binding Capacity (OBC) serves as a measure of oil loss under extreme conditions. To assess this, the samples were centrifuged to extract the unbound liquid oil. OBC decreased slightly from 95.17% for the oleogel (OLEO) to 89.39% for the emulgel (EM) and further to 87.45% with the phenolic-enriched emulgel (EMEX) (Fig. 2). This decrease is consistent with the literature, where emulgels have a slightly lower oil-binding capacity than oleogels due to their complex multi-phase structure, but the addition of phenolics could further influence the oil retention properties. Waxes are considered highly promising structuring agents because of their ability to retain oil even at low concentrations, which makes them cost-effective and suitable for food applications (Patel, 2015).

In comparison with other studies, our results verify that the oleogel system, in this case, the OLEO formulation, exhibits the highest OBC (Sun et al., 2022), which is consistent with its superior structural integrity as observed in the texture profile analysis. This study confirms that phenolic compounds in the emulgel system may affect its structural properties, but the influence on OBC is less pronounced compared to the oleogel system.

Firmness decreased from 4.26 N in OLEO to 4.02 N in EM and 3.83 N in EMEX. Similar findings were reported for oleogels prepared from rapeseed oil and 5% beeswax (Kupiec et al., 2020). Our results confirm that the addition of water and phenolic compounds in the emulgel system leads to a decrease in firmness, which is expected due to the disruption of the gel structure caused by the water phase and the phenolic interactions.

The melting temperature is a critical quality characteristic in plastic fats, determining their suitability for various applications (Yılmaz and Öğütcü, 2014). The melting points followed a similar trend, with the OLEO having the highest melting temperature at 50.42 °C, followed by the EM (44.44 °C) and EMEX (40.38 °C) (Fig. 2). These findings support the existing knowledge that emulsification and the incorporation of phenolic compounds interfere with the crystallization process, thereby lowering the melting point (Moghtadaei et al., 2018).

Emulsification introduces an oil-water phase separation, which disrupts the crystallization of the gel network, especially in systems containing beeswax. The presence of water in the emulgel system (EM) leads to a less ordered gel structure, resulting in lower melting points compared to the oleogel (OLEO). The oil and water phases in the emulgel system form a more disordered matrix, preventing the wax components from forming a tightly packed crystalline structure, which typically contributes to a higher melting point.

In addition, the incorporation of phenolic compounds in the EMEX system can further disrupt the crystallization process, as the phenolics may interact with the gelator (beeswax), causing additional structural disorder. This interference with the wax crystallization results in a further reduction in the melting temperature of the EMEX system. In comparison, similar results were obtained for sesame oil-beeswax oleogels with varying concentrations, further validating the observed trends in melting temperature (Sivakanthan, 2024; Sivakanthan et al., 2023).

|

Fig. 2 Physical, color, texture and viscosity properties of sunflower oil-beeswax oleogel and emulgel. OLEO = sunflower oleogel, EM = sunflower emulgel, EMEX = sunflower emulgel with onion peel phenolic extract. |

3.2.2 Color properties of sunflower oil-beeswax oleogel and emulgel

Figure 2B presented the color properties of OLEO, EM, and EMEX. The L* value, representing lightness, ranged from 55.62 for OLEO to 52.34 for EM, while the addition of phenolic extract resulted in a decrease to 50.16.

The lightness of EM was lower than OLEO due to the incorporation of water in the emulsion. This was in agreement with Keskin Uslu and Yılmaz (2021) who reported that as the added water level increased, the L value decreased slightly. However, the introduction of onion extract, which may have darker pigmentation, leads to a reduction in lightness. Onion extract, rich in phenolic compounds, can introduce more color, affecting the overall lightness of the emulgel.

The results for color b showed a gradual increase from OLEO (2.15) to EM (2.56), and EMEX (2.93), indicating an intensified yellow hue as the structure became more complex. This could be attributed to the presence of phenolic extract which increased the b* value, likely due to the yellow-brownish hues of phenolic compounds. These findings are consistent with previous study of Keskin Uslu and Yılmaz (2021) who noted adding water in the emulgels caused more yellowness.

For a, no significant differences were observed between samples. Negative numbers for a also were reported by Keskin Uslu and Yılmaz (2021) for oleogel and emulgel samples.

As all the samples exhibited a creamy-white color, there should be no issues with their use in real-world food or non-food applications.

3.2.3 Chemical properties of sunflower oil-beeswax oleogel and emulgel and total phenolic content (TPC) and antioxidant acticity (DPPH %) compounds extracted from sunflower oil-beeswax oleogel and emulgel

The total phenolic content (TPC) of the sunflower oil (4.15 mg GAE/g), oleogel (OLEO) (4.55 mg GAE/g), and emulgel (EM) (4.35 mg GAE/g) showed similar values, with no statistically significant differences among them (Tab.2). However, when phenolic extract was added to the emulgel (EMEX), TPC significantly increased to 5.49 mg GAE/g, confirming the contribution of the added onion peel extract, which is rich in antioxidants such as quercetin and kaempferol.

DPPH antioxidant activity showed a similar trend, with sunflower oil exhibiting a DPPH value of 29.25%. The activity increased slightly for OLEO (30.23%) and EM (29.88%). However, the addition of the phenolic extract in EMEX resulted in a significant increase in antioxidant activity (38.84%), due to the potent antioxidant properties of the onion peel extract.

Free fatty acid (FFA) content was relatively consistent across all samples, ranging from 2.59% to 2.77%, indicating that the addition of wax, water, or phenolic extracts did not significantly influence the free fatty acid content.

Peroxide values (PV), which measure oxidative rancidity, remained stable across all formulations, ranging from 3.44 to 3.65 meq O2/kg. The lack of significant change in PV can be attributed to the fact that the systems were not subjected to prolonged storage conditions or oxidative stress, meaning no significant oxidation occurred during the experiment. These values are comparable to those reported in the literature for fresh sunflower oil and oleogel systems, which typically range between 2.0 and 5.0 meq O2/kg (Marangoni and Garti, 2018; Hwang, 2020), indicating that the formulations in this study maintained acceptable oxidative stability within expected limits.

Finally, all formulations demonstrated stability under centrifugation, which was evaluated to assess the physical integrity of the systems under mechanical stress. The oleogel (OLEO) and emulgel (EM) systems exhibited no phase separation or significant degradation during centrifugation, indicating that the gel networks formed by the structuring agents, such as beeswax, were resilient to mechanical stress (Zhou et al., 2024). This result suggests that both systems are physically stable and capable of maintaining their structural integrity under conditions that would typically challenge the stability of emulsions and gelled systems. The inclusion of phenolic extract in the EMEX system did not compromise this stability, as no significant changes were observed in the structure or phase distribution following centrifugation. This finding is important, as it suggests that the addition of bioactive compounds, such as the onion peel extract, does not adversely affect the physical stability of the emulgel, making it a promising system for food applications where both structural integrity and antioxidant functionality are required.

Total phenolic content (TPC), antioxidant activity (DPPH) and chemical properties of sunflower oil-beeswax oleogel and emulgel.

3.2.4 The texture properties of sunflower oil-beeswax oleogel and emulgel

The texture properties of the sunflower oil-beeswax oleogel and emulgel are critical in understanding their functionality and suitability for various food applications. The results (Fig. 2C) demonstrated significant variations in hardness, adhesiveness, cohesiveness, and springiness between the systems. The OLEO system exhibited the highest hardness value (3.1), followed by EM (2.9) and EMEX (2.8). The higher hardness of OLEO can be attributed to the solid-like structure of the oleogel, which is created by the formation of a beeswax network. The rigidity of this structure enhances its ability to resist deformation, which is typical of oleogels. On the other hand, emulgels, such as EM and EMEX, contain both oil and water phases stabilized by emulsifiers, resulting in a softer texture due to their higher liquid content and more flexible matrix (Han et al., 2014).

Adhesiveness measures the energy required to break the bond between the product and a surface. The EMEX system demonstrated the highest adhesiveness (0.7 mJ), followed by OLEO (0.6 mJ) and EM (0.5 mJ). Adhesiveness is important for food systems, as it affects how the product interacts with the mouth. The higher adhesiveness in EMEX could be related to the increased molecular interactions in the emulgel matrix with the addition of phenolic extract. The phenolic compounds may act as natural binders, contributing to higher surface stickiness (Tanislav et al., 2022). This observation is important for applications where adhesion to surfaces or controlled release of active compounds is desired.

Cohesiveness reflects the internal strength of the bonds within the product, with higher values indicating a stronger cohesion. The cohesiveness was slightly enhanced in EMEX (0.39), followed by EM (0.38) and OLEO (0.36). The increase in cohesiveness in EMEX could be attributed to the addition of phenolic compounds, which may enhance the gel matrix through non-covalent interactions—such as hydrogen bonding and hydrophobic associations—leading to a more compact and tightly bound structure. Previous studies have noted that cohesiveness is crucial in determining the ability of a system to withstand deformation and recover its original form (Tanislav et al., 2022). The values obtained in this study are consistent with previous research on oleogels, which reported cohesiveness values ranging from 0.05 to 0.21 for various gelators (Tanislav et al., 2022; Lim et al., 2017).

Springiness, or the ability of the sample to return to its original shape after deformation, was measured for all three systems. The results showed similar springiness values: OLEO (2.84 mm), EM (2.92 mm), and EMEX (2.91 mm). These values indicate that all the systems exhibit comparable elasticity, with only slight variations that were not statistically significant. The springiness of the systems was influenced by the matrix structure, with both oleogels and emulgels demonstrating relatively high elasticity, indicative of their ability to recover shape after compression.

In conclusion, the texture properties of the oleogel and emulgel systems are influenced by the gelation structure, the presence of phenolic compounds, and the interactions between the oil, water, and structuring agents. The OLEO system, with its higher hardness, lower adhesiveness, and slightly lower cohesiveness, is indicative of a more rigid, solid-like structure. In contrast, the EM and EMEX systems, with their lower hardness and higher adhesiveness, exhibit more flexible and less rigid structures, with the phenolic extract in EMEX contributing to increased cohesiveness. It is important to note that these textural characteristics are specific to the formulations studied here and may vary with different gelator types, concentrations, or oil phases. These findings highlight the functional and sensory implications of these systems, particularly in applications where textural properties like adhesiveness, cohesiveness, and springiness are important.

|

Fig. 3 AFM, SEM and DSC of sunflower oil-beeswax oleogel and emulgel. |

|

Fig. 4 Texture analysis of burger samples. OLEO = sunflower oleogel, EM = sunflower emulgel, EMEX = sunflower emulgel with onion peel phenolic extract. |

3.2.5 Viscosity of sunflower oil-beeswax oleogel and emulgel under different temperature

The viscosity results confirmed the well-known trend that increasing temperature leads to a decrease in viscosity for all systems. At 30 °C, EMEX exhibited the highest viscosity (2041.67 cP), followed by OLEO (2016.67 cP), and EM (1991.67 cP), indicating that the presence of phenolic compounds in EMEX may enhance the gel matrix and network structure (Fig. 2). As temperature increased to 50 °C, the viscosity for all systems decreased, with OLEO showing 1551.28 cP, EM 1422.62 cP, and EMEX 1361.11 cP. The more substantial viscosity drop in the emulgel systems (EM and EMEX) could be attributed to the weakening of the oil-water emulsion structure at higher temperatures (Xia et al., 2022). At 80 °C, OLEO retained the highest viscosity (1196.15 cP), while EM and EMEX exhibited lower viscosities of 1080.36 cP and 1025.85 cP, respectively.

While the decrease in viscosity with increasing temperature is well established, the comparison of the oleogel and emulgel systems in this study provides useful insights into how phenolic compounds influence the thermal stability and viscosity behavior of structured food systems, particularly under conditions where temperature changes are expected. The addition of phenolic extract in EMEX was found to enhance viscosity at lower temperatures, which could contribute to the stability and texture of food products during storage and processing.

3.2.6 Fatty acids composition of sunflower oil-beeswax oleogel and emulgel

Palmitic and stearic acids were the major saturated fatty acids (SFA) in all samples. The amount of SFA remained fairly consistent across sunflower oil, OLEO, and emulgels (Tab 3). The formation of oleogels and emulgels, which involved structuring the oil with beeswax, did not significantly affect the fatty acid profile. Oleic acid was the predominant monounsaturated fatty acid. It showed a slight decrease in OLEO, EM and EMEX compared to the original sunflower oil. Linoleic acid is the most abundant fatty acid across all samples, but its concentration decreases in the oleogel and emulgel formulations. Similarly, the linolenic acid content also slightly decreases. The decrease in oleic and linoleic acids content during the formation of oleogels and emulgels could be due to the processing conditions, including temperature and shear during gelation or emulsification. Research by Moghtadaei et al. (2018) showed that structuring oil with beeswax different concentrations typically retained the original fatty acid composition.

Fatty acids composition of sunflower oil-beeswax oleogel and emulgel.

3.2.7 Sensory evaluation of sunflower oil-beeswax oleogel and emulgel

The sensory evaluation of sunflower oil-based oleogel (OLEO) and emulgel (EM and EMEX) showed notable variations in terms of appearance, spreadability, taste, odor, and overall acceptability (Tab. 4).

For appearance, EMEX received the highest score (8.35), followed by EM (7.83) and OLEO (7.42). The higher appearance score for EMEX can likely be attributed to the presence of phenolic compounds, which could have contributed a subtle sheen or color to the emulgel, enhancing its visual appeal. This observation aligns with previous research, such as Pintado and Cofrades (2020), who found that natural extracts can enhance the appearance of emulsions due to their color-contributing properties. This visual enhancement could make the product more appealing to consumers.

Regarding spreadability, EMEX (8.69) and EM (8.63) scored higher than OLEO (7.85). This difference is primarily due to the structural properties of these systems. Emulgels, with their combination of both oil and water phases, tend to have a smoother, more pliable structure, making them easier to spread. In contrast, oleogels, with their solid-like network formed by the beeswax gelation, tend to be more rigid and less spreadable (Milutinov et al., 2023). Although the addition of phenolic extract in EMEX did not significantly affect spreadability, it maintained the superior spreadability of the emulgel systems compared to the oleogel. This demonstrates the inherent advantage of emulgels in terms of spreadability, making them more consumer-friendly in applications that require easy spreading.

For taste and odor, there were no significant differences between the three samples. This suggests that the structural differences between the oleogel and emulgel systems did not influence the basic sensory characteristics like taste or odor, indicating that these systems may perform similarly in terms of flavor profile and scent.

However, overall acceptability showed significant differences. Both EM (8.88) and EMEX (8.84) were more acceptable than OLEO (8.38). This higher acceptability for emulgels can be attributed to several factors, including their smoother texture, better spreadability, and possibly more pleasing mouthfeel (Yılmaz, 2022). Emulgels, due to the presence of both oil and water phases, likely have a more light, creamy texture compared to oleogels, which are more solid and dense (Pușcaș et al., 2020). The higher acceptability of emulgels, particularly EMEX, could also be influenced by the antioxidant properties provided by the phenolic extract, which may enhance the overall perception of quality. Furthermore, the lighter texture and superior spreadability of emulgels could make them more suitable for a wider variety of consumer applications.

In summary, the sensory evaluation revealed that emulgels (EM and EMEX) were favored over oleogels (OLEO), mainly due to their superior spreadability, smoother texture, and higher overall acceptability. The addition of phenolic extract in EMEX did not significantly affect spreadability but contributed to a higher acceptability score. This suggests that the emulgel system, particularly with the addition of bioactive compounds like onion peel phenolics, offers promising functional and sensory benefits, making it a desirable option for food formulations that prioritize texture and overall consumer satisfaction.

Sensory evaluation of sunflower oil-beeswax oleogel and emulgel.

3.2.8 SEM of sunflower oil-beeswax oleogel and emulgel

The SEM images (Fig. 3A, B, C) showed distinct microstructural differences between OLEO, EM, and EMEX. OLEO exhibited a relatively smooth and homogeneous surface structure with spherical voids or pores, characteristic of a stable oleogel matrix made from sunflower oil and beeswax. The visible round pores suggested uniform gelation, indicating that the beeswax had effectively trapped the sunflower oil within the gel matrix, providing structural integrity and reducing movement of the oil. This stable, uniform matrix in OLEO is consistent with the high hardness value observed for OLEO (3.1), indicating a more rigid, solid-like structure. The gelation network formed by the beeswax matrix likely contributes to OLEO’s superior oil retention capacity (OBC) of 95.17%, as the wax network effectively traps the sunflower oil, preventing oil leakage even under extreme conditions.

For EM, the introduction of water and Tween 80 into the system transformed the structure into a more irregular and disrupted appearance. The presence of both oil and water phases, emulsified using Tween 80, introduced more complexity into the microstructure, with larger, irregularly shaped particles and fragments (Carpintero-Tepole et al., 2017). The surface appeared more disorganized, which was typical for emulsions where oil droplets were dispersed within an aqueous medium. This complexity correlates with the lower hardness values observed for these systems (EM: 2.9, EMEX: 2.8), as the emulsion structure is generally more flexible and less rigid than oleogels. The OBC values for EM (89.39%) and EMEX (87.45%) were also lower than OLEO, likely due to the added water phase, which reduces the oil-binding capacity of the system.

For EMEX, the addition of the phenolic extract further altered the microstructure, as evidenced by the rough, fragmented surface with larger, blocky particles (Ngo et al., 2022). The microstructure appeared more irregular and coarse, with larger aggregates, indicating that the phenolic extract may cause phase separation or aggregation of components within the emulgel. The presence of phenolic compounds in EMEX did not significantly improve the OBC compared to EM, although it did enhance cohesiveness (0.39 in EMEX) and adhesiveness (0.7 mJ), which can be attributed to the interaction between the phenolic extract and the emulgel matrix. These changes in the microstructure are likely responsible for the increase in cohesiveness and adhesiveness in EMEX, further influencing the texture properties observed in the rheological tests (Min et al., 2023).

The oil-binding capacity (OBC) of the systems can be directly linked to the observed microstructural differences in the SEM images. OLEO, with its solid-like network formed by beeswax, exhibited the highest OBC (95.17%), indicating that the rigid, well-structured gel matrix is highly effective at trapping oil. The SEM results support this, showing a stable, uniform matrix with spherical pores, which suggests that the oleogel can maintain its integrity and oil retention even under challenging conditions.

On the other hand, the lower OBC in EM (89.39%) and EMEX (87.45%) corresponds to the more complex microstructure observed in their SEM images, where larger, irregular particles and phase separation were seen. These disruptions in the microstructure could result in a less stable network, thereby reducing the ability of the system to retain oil. While the addition of phenolic compounds in EMEX led to some structural changes (as seen in the rougher, more fragmented surface in SEM images), the impact on OBC was less pronounced, as the complex oil-water phases could limit the gel’s oil-holding capacity.

It should be noted that the SEM images represent the microstructure of the samples after preparation steps, including freezing, drying, and gold coating. These processes may introduce artifacts such as shrinkage, oil migration, or changes in surface texture, which can affect the true native morphology of the oleogel and emulgel systems. Therefore, while the SEM images provide valuable insights into the structural differences between formulations, the interpretations should be considered indicative rather than definitive of the native gel structures.

In summary, the SEM images helped elucidate the microstructural differences between the oleogel and emulgel systems, which in turn are reflected in the texture properties (hardness, cohesiveness, and adhesiveness) and OBC values. The rigid network in OLEO resulted in higher OBC and hardness, while the more flexible and complex structure of EM and EMEX contributed to lower OBC and softer texture. The phenolic extract in EMEX contributed to increased cohesiveness and adhesiveness, as seen in both the SEM images and the texture profile analysis.

3.2.9 AFM of sunflower oil-beeswax oleogel and emulgel

The AFM images of OLEO, EM, and EMEX revealed interesting differences in surface morphology and nanostructural features, which influenced their physical properties and potential applications (Fig. 3D, E, F).

The first image (OLEO) showed a relatively smooth surface with nano-scale aggregates. The uniformity of the surface and slight elevation (up to 1.4 μm) suggested a homogeneous distribution of the beeswax within the sunflower oil, creating a stable network that could enhance the oleogel’s structural integrity and oil-holding capacity. This smooth texture was indicative of good gelation, with small, well-distributed aggregates that contributed to the oleogel’s solid-like properties (Zhang et al., 2023).

The second image (EM) showed a much more uneven surface, with larger and more pronounced peaks and valleys (up to 1.9 μm). The introduction of water and Tween 80 disrupted the homogeneity seen in the oleogel, leading to a more complex structure (Zhang, 2020). The emulgel’s surface suggested increased aggregation and clustering of components, likely due to the emulsification process. The water phase interacted with the oil and beeswax network, causing phase separation and leading to larger nanostructures (Naderizadeh et al., 2019). This indicated the formation of a more complex gel matrix, which could affect its viscosity and stability.

For EMEX showed a rough surface similar to the second, but with more defined pits and irregularities. The addition of extract introduced bioactive compounds, which may further disrupt the emulsion system and contribute to the increased surface irregularity (Boostani et al., 2024). The roughness and variability in texture suggested interactions between the extract’s phenolic compounds and the beeswax-oil matrix, potentially improving the antioxidant properties of the emulgel but also affecting its structural stability. This texture could enhanced bioactive release but may compromise some mechanical stability compared to the simpler emulgel.

3.2.10 DSC of sunflower oil-beeswax oleogel and emulgel

Figure 3G, H, I showed DSC curves of OLEO, EM ad EMEX. The DSC curve for OLEO sample showed a glass transition temperature (Tg) of 44.18 °C, a melting temperature (Tm) of 158.92 °C, and a decomposition temperature (Td) of 249.08 °C. The enthalpy change during melting was also indicated (129.03 J/g), which was a measure of the energy required for phase transitions. These thermal events corresponded to the melting and crystallization behavior of the oleogel, which was influenced by the beeswax structuring the oil (Martins et al., 2017). The thermal stability up to 249 °C indicated that the oleogel could withstand significant heat before breaking down.

In EM, the DSC curve showed a slightly higher glass transition temperature (Tg) of 49.22 °C and a higher melting temperature (Tm) of 173.29 °C compared to the oleogel. The decomposition temperature (Td) is 228.30 °C. The presence of water and the emulsifying agent (Tween 80) likely resulted in a more thermodynamically stable system, as indicated by the higher melting temperature and larger enthalpy (198.71 J/g) compared to the oleogel. However, the slight decrease in Td might suggest a reduced thermal stability due to the emulsification process and added water.

For EMEX, the glass transition temperature (Tg) was observed at 51.14 °C, which may be attributed to the amorphous regions within the emulgel matrix, likely arising from hydrophilic components such as Tween 80 and phenolic extract. The main thermal event observed at approximately 174.82 °C is interpreted not as the melting point of beeswax (typically 60–65 °C) but rather as an indication of thermal degradation or a high-temperature phase transition within the composite system. The onset of decomposition (Td) was noted at 233.16 °C, suggesting that the addition of the phenolic extract slightly enhanced the thermal stability of the emulgel matrix. The extract might be providing additional stability due to its antioxidant properties, which could reduce the rate of thermal degradation (Chaaban et al., 2017). Additionally, the enthalpy (210.12 J/g) was higher than EM, indicating that the extract might contribute to stronger molecular interactions or changes in the crystallization behavior of the emulgel. These results were in agreement with Yaqoob et al. (2024) who reported that DSC results exhibited improved melting points of the multicomponent oleogel.

The DSC curve for the OLEO sample showed a glass transition temperature (Tg) of 44.18 °C, a melting temperature (Tm) of 158.92 °C, and a decomposition temperature (Td) of 249.08 °C. The enthalpy change during melting was also indicated (129.03 J/g), which was a measure of the energy required for phase transitions. These thermal events corresponded to the melting and crystallization behavior of the oleogel system, which includes both beeswax and sunflower oil. It is important to note that the reported Tg and Tm values correspond to the oleogel system, not to pure beeswax, as the combination of beeswax and sunflower oil can alter the thermal properties. The thermal stability up to 249 °C indicated that the oleogel could withstand significant heat before breaking down.

In addition to the oleogels, the DSC analysis for the emulgels (EM and EMEX) showed that the presence of water and emulsifiers such as Tween 80 in EM and the addition of phenolic extract in EMEX had significant effects on their thermal properties. EM exhibited a higher Tm and enthalpy compared to OLEO, suggesting that emulsification leads to a more thermodynamically stable system. The introduction of water and emulsifiers in EM likely disrupted the crystallization behavior of the oleogel network, leading to a lower Td. The addition of phenolic compounds in EMEX increased the Tg and enthalpy, indicating that the phenolics contributed to stronger molecular interactions in the emulgel matrix, further affecting the system’s thermal behavior.

3.3 Development and characterization of burger samples

3.3.1 Physical and chemical properties of prepared burger

The pH values of the burger samples ranged from 6.84 to 7.11, with the control burger having the lowest pH (6.84) and the oleogel burger showing the highest pH (7.11). However, no significant differences in pH were observed between the samples (Tab. 5). These slight variations in pH could be attributed to the incorporation of different systems, such as oleogel and emulgel, into the burger formulations. Despite these small differences, the overall pH remained similar across all samples, and the changes did not lead to any meaningful variations in the overall chemical properties of the burgers.

In general, color plays a significant role in consumers’ decisions to either purchase or reject a package of meat, as it is often associated with the freshness and potential spoilage of the product (Singh et al., 2011). The L* (lightness) values showed that the control, OLEO, and EM burgers had similar lightness values, with no significant differences observed between the samples (Control: 45.62, OLEO: 44.52, and EM: 45.23). The EMEX burger, however, showed a slightly lower L* value of 43.99, indicating a slight darkening of the meat. This decrease in lightness could be attributed to the phenolic compounds in the onion peel extract. Phenolic compounds, such as quercetin and kaempferol, are known to interact with proteins, which could influence the color of the meat, especially under heat treatment (Zhang et al., 2021; Paesa et al., 2022). The darkening effect is likely due to these phenolic compounds, which might have facilitated the Maillard reaction or contributed to the formation of darker pigments within the meat (Zhang et al., 2015).

The a* (redness) and b* (yellowness) values showed minimal variations across the samples, with no significant differences observed between the control, OLEO, EM, and EMEX. This suggests that while slight differences in color were detected, they were not substantial enough to affect the overall appearance of the burger. These findings are consistent with the existing literature, which suggests that phenolic compounds may have a more pronounced effect on lightness (L*) than on the redness (a*) or yellowness (b*) of meat products (Issara et al., 2022).

Color changes in restructured meat products during storage can result from various reactions, including the Maillard reaction, lipid oxidation, and the oxidation of myoglobin (Chaijan et al., 2021). In this study, the phenolic compounds in the EMEX burger could have interacted with the meat’s amino acids, which may have led to the observed color change, particularly during heat treatment.

Additionally, comparing the current findings with other studies using sunflower oil-based structuring systems or similar structuring agents (such as beeswax) would provide a more relevant context. Studies that utilized sunflower oil and beeswax-based structuring agents (Ferdaus et al., 2024) have mentioned similar effects on color.

da Silva et al. (2019) observed a difference in the a* value of the oleogel meat product, but no significant changes were noted for the L* and b* values. Conversely, a study by Heck et al. (2019) reported similar findings to our study regarding the color attributes (excluding L*). They examined low-fat burgers made with a hydro-gelled emulsion containing a mixture of chia and linseed oils.

Additionally, Moghtadaei et al. (2018) discussed the use of sesame oil oleogel, stabilized with beeswax, as a fat substitute in beef burgers at concentrations of 5%, 7.5%, and 10%. Also, they reported that there were no significant differences in the a* and b* values between samples as the proportion of oleogel increased in burger production. While Sadeghinejad et al. (2019) found that L* value decreased in burger samples prepared by phenolic compounds.

The water-holding capacity (WHC) was highest in the control burger (27.21%) and lowest in the oleogel and emulgel burgers, indicating that replacing animal fat with oleogel and emulgel slightly reduced the ability of the meat matrix to retain water. This lower WHC can be attributed to the structural properties of the fat alternatives (Tian et al., 2025). Oleogels and emulgels form more rigid, hydrophobic matrices compared to animal fat, which is more hydrophilic and capable of holding water more effectively (Pinto et al., 2021). Specifically, oleogels are structured by gelators, such as beeswax, which create a solid-like matrix optimized for trapping oils but not as effective in retaining water. This hydrophobic network limits the ability of the system to absorb and hold water, unlike animal fat, which has a higher affinity for water molecules (Jimenez-Colmenero et al., 2015).

Furthermore, the presence of emulsifiers in emulgels introduces an additional layer of complexity. While emulsifiers stabilize oil droplets in the system, they do not maximize water retention, leading to a reduced WHC compared to animal fat. The structural integrity of the emulsion matrix in the emulgels, designed to stabilize both oil and water phases, does not facilitate the retention of large amounts of water, further contributing to the lower WHC observed in these systems (O’Sullivan et al., 2016).

This reduced water retention in both oleogel and emulgel systems can be linked to their inability to form the same type of protein-water interactions found in traditional meat systems, where water is held by both fat and protein components (Asyrul-Izhar et al., 2023). Consequently, the lower WHC observed in the oleogel and emulgel burgers is primarily due to the structural characteristics of these fat alternatives, which do not possess the same water-binding capabilities as animal fat.

Cooking loss was lowest in the control burger (25.84%) and highest in EM ad EMEX burgers (29.63 ad 29.87%, respectively). The higher cooking loss in the emulgel samples may be attributed to the higher moisture content in the emulsion system, leading to greater water release during cooking. This finding is consistent with studies such as that by Pintado and Cofrades (2020), where fat replacement in meat products, particularly using emulgels, led to increased cooking loss due to higher moisture migration during thermal treatment.

pH, color, water holding capacity (WHC) and cooking loss (CL) of burger samples.

3.3.2 Texture analyzer of prepared burger

The texture characteristics of food play a crucial role in assessing the overall quality, especially in meat and meat-related products (de Souza Paglarini et al., 2018; Gómez-Estaca et al., 2019).

The control burger had the highest hardness value (20.15), indicating a firmer texture compared to the oleogel and emulgel samples (Fig. 4). This higher hardness was likely due to the presence of solid animal fat (Fig. 4), which provided structure and firmness. In contrast, the hardness of OLEO (17.52), EM (15.37), and EMEX (15.22) burgers was significantly lower. The reduction in hardness could be attributed to the softer texture of oleogels and emulgels, which lack the solid fat crystals present in animal fat. The hardness of meat products can be attributed to the smaller size of fat globules. During production, these fat globules become encased in salt-soluble proteins, particularly myosin and actin, which create a protein film around the globules. Smaller fat globules require a significantly larger amount of this interfacial protein film. As the formation of the protein film increases, the product’s hardness also rises. Consequently, the presence of larger fat globules may explain the reduction in hardness when animal fat is replaced (Youssef and Barbut, 2009).

The control burger showed the lowest cohesiveness value (0.52), while OLEO (1.12), EM (1.20), and EMEX (1.18) had significantly higher values. Higher cohesiveness in these samples suggested that the fat alternatives better bind the burger matrix, leading to a more cohesive product. This was likely due to the gel-like structure of oleogels and emulgels, which enhanced the binding between protein and water.

The control burger had the highest chewiness value (2.84), which correlated with its higher hardness. Chewiness was reduced in OLEO (1.88), EM (1.79), and EMEX (1.65) burgers, likely due to their softer texture. As hardness decreased, so did the effort required to chew the product.

Springiness was highest in OLEO (2.22), EM (2.19), and EMEX (2.20) burgers (without any significant differences), compared to the control (0.47). This indicated that the fat replacers created a more elastic texture. The gel structure of oleogels and emulgels may have contributed to better recovery after compression, as these systems are known to enhance the elasticity of meat products. Study by Oppong et al. (2022) showed an increase in springiness emulgel formulated nugget I comparison with control nuggets.

Overall, these findings suggested that replacing animal fat with oleogels and emulgels leads to softer, more cohesive, and elastic textures, which may affect the mouthfeel and consumer preference. The addition of onion phenolic extract did not significantly affect the texture attributes compared to the plain emulgel, suggesting its impact was primarily on flavor rather than texture. Similar results were reported by Oppong et al. (2022) who reported that fish nuggets control showed higher hardness than the ones prepared by emulgel.

During the emulsification process, it is important to balance the water immobilized by hydrocolloids with the amount of water available to interact with meat proteins. This balance is key to reducing hardness and enhancing the elasticity of the emulsion-based gel system (Mejia et al., 2019). Also, Wu et al. (2011) proposed that pre-emulsified vegetable oil may enhance the gel-forming ability and structure, depending on the oil type. A reduction in cohesiveness and adhesiveness was noted as emulgel concentration increased, indicating the disruption of the continuous protein matrix by incorporating the emulgel into the fish nugget structure. This outcome aligned with the findings of Baer and Dilger (2014), who reported that the addition of emulsified corn oil to sausage resulted in a reduction in its hardness, chewiness, and springiness. Likewise, burger patties prepared with emulsified avocado oil as a substitute for back fat exhibited reduced hardness, gumminess, and chewiness compared to those made with back fat (Rodríguez-Carpena et al., 2012). No changes in cohesiveness and adhesiveness were observed as the storage time progressed (Oppong et al., 2022). This aligns with the findings of Álvarez et al. (2012), who noted that incorporating walnut extract into a rice bran oil emulsion enhanced gel network formation and elasticity compared to back fat emulsions, with no significant changes in springiness during frozen storage. Based on the results, the inclusion of sunflower oleogel and emulgels in burgers reduced hardness and cohesiveness while increasing springiness and chewiness. Similar results for hardness and chewiness for burger were reported by Moghtadaei et al. (2018).

Laredo et al. (2011) suggested that the hardness of fats is influenced by the degree of unsaturation in fatty acids. A higher number of double bonds in triglycerides increases their flexibility, allowing for tighter aggregation. This observation aligns with our findings on the hardness of the burger samples.

3.3.3 Sensory evaluation of prepared burger