| Issue |

OCL

Volume 31, 2024

Extraction solvents / Solvants d’extraction

|

|

|---|---|---|

| Article Number | 31 | |

| Number of page(s) | 12 | |

| DOI | https://doi.org/10.1051/ocl/2024027 | |

| Published online | 13 December 2024 | |

Review

Solvent solutions: comparing extraction methods for edible oils and proteins in a changing regulatory landscape. Part 1: Physical-properties☆

1

Terres Inovia, 11 rue G. Monge, 33610 Canéjan, France

2

PPM, Berliner Chaussee 66, 39114 Magdeburg, Germany

* Corresponding author: p.carre@terresinovia

Received:

23

September

2024

Accepted:

28

October

2024

In the context of potential regulatory changes, this study compares the properties of various solvents for the extraction of edible oils. The solvents considered are hexane isomers, alcohols, ketones, ethyl acetate, dichloromethane and 2-methyloxolane. The study presents a detailed table of physical properties for each solvent, including boiling point, density, vapour pressure, flash point and miscibility with water. It also addresses chemical stability, reactivity and potential interactions of these solvents with oilseeds. Particular attention is given to solvent-substrate interactions measured by Hansen solubility parameter. Normal hexane and its isomers show high affinity for neutral lipids, a lesser one for polar lipids and fair selectivity for non-lipids. Due to their hydroxyl group, alcohols (methanol, ethanol, isopropanol) exhibit only a modest affinity for non-polar lipids, though this affinity increases with the number of carbon atoms in the alcohol molecule. They demonstrate a higher efficacy in extracting polar lipids; however, this extraction process also extends to numerous non-lipidic molecules. Ketones (acetone, MEK) offer a balance, with theoretically good affinity for both polar and non-polar lipids, although in practice they do not dissolve phospholipids. Ethyl acetate shows good solvent power for various lipids, its ester group being found in most of lipid molecules. Dichloromethane is a good solvent for lipids in general but raises potential safety concerns. 2-Methyloxolane is noted for its ability to efficiently extract both polar and non-polar lipids, offering a potential compromise between hexane-like and more polar solvents however, it is potentially hindered by its price and its limited availability.

Résumé

Dans le contexte d’une évolution potentielle de la réglementation, cette étude compare les propriétés de divers solvants dans le cadre de l’extraction des huiles alimentaires. Les solvants pris en compte sont les isomères de l’hexane, les alcools, les cétones, l’acétate d’éthyle, le dichlorométhane et le 2-méthyloxolane. L’étude présente un tableau détaillé des propriétés physiques de chaque solvant, comprenant le point d’ébullition, la densité, la pression de vapeur, le point d’éclair et la miscibilité avec l’eau. Elle aborde également la stabilité chimique, la réactivité et les interactions potentielles de ces solvants avec les matières oléagineuses. Une attention particulière est portée aux interactions solvant-lipides mesurée par les paramètres de solubilité de Hansen. Le n-hexane et ses isomères montrent une forte affinité pour les lipides apolaires, une moindre capacité envers les lipides polaires et une bonne sélectivité pour les non-lipides. En raison de leur groupe hydroxyle, les alcools (méthanol, éthanol, isopropanol) montrent une faible affinité pour les lipides apolaires quoique celle-ci augmente avec leur nombre de carbones. Ils démontrent une meilleure efficacité dans l’extraction des lipides polaires qui s’accompagne d’une propension à extraire de nombreuses molécules non-lipidiques. Les cétones (acétone, MEK) offrent un équilibre, avec théoriquement une bonne affinité pour les lipides polaires et non polaires quoi qu’en pratique ils ne dissolvent pas les phospholipides. L’acétate d’éthyle montre un bon pouvoir solvant pour divers lipides, son groupe ester étant commun à de nombreux lipides. Le dichlorométhane est un bon solvant les lipides en général, mais il soulève des préoccupations potentielles en matière de sécurité. Le 2-méthyloxolane est remarqué pour sa capacité à extraire efficacement les lipides polaires et non polaires, toutefois il est potentiellement handicapé par son prix et sa disponibilité limitée.

Key words: Solvents / extraction / Hansen solubility parameters / volatility

Mots clés : Solvants / extraction / paramètres de solubilité de Hansen / volatilité

© P. Carré et al., Published by EDP Sciences, 2024

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Highlights

Solvents for edible oil extraction comparison.

Examines hexanes, alcohols, ketones, ethyl acetate, dichloromethane, 2-methyloxolane.

Details physical properties: boiling point, density, vapor pressure, flash point, water miscibility.

Uses Hansen solubility parameters for solvent-substrate interactions.

1 Introduction

In the European Union, the list of solvents allowed for the processing of food ingredients, their conditions of use and maximum residues are given in the Annex of the Directive 2009/32/CE (European Parliament and Council of the Europa Union, 2009). This annex can be modified at the demand of industrialists proposing new solvents or after a possible recommendation of the EU authority for food safety (EFSA). The list is composed of three parts. Part one considers solvents allowed for all uses. It lists propane, butane, carbon dioxide and nitrogen protoxide, which are gaseous and excluded here because not usable in the industry. Only three liquid solvents are available in the first list: ethanol (EtOH), ethyl acetate (EA) and acetone, the latter being forbidden for the refining of olive-pomace oil. The second part contains solvents which use are specified as well as their residues level in the food ingredients. Regarding the extraction of vegetable oils, hexane, defined as a mixture of acyclic C6 saturated alkanes boiling between 64 and 70 °C is allowed for the extraction and the fractionation of animal fats and vegetable oils. Methyl-ethyl-ketone (MEK) is not directly allowed for extraction but for the fractionation of oils and fats. Dichloromethane or methylene chloride (DCM) is also a possible solvent which is not currently allowed for oil extraction but could have good technical characteristics for this objective. Its specified use is limited to decaffeination of coffee and tea. Methanol (MeOH) and isopropanol or propan-2-ol (IPA) are allowed for all uses but with limited residues in the final foods (10 mg/kg). We also included cyclohexane, the cyclic isomer of hexane which is allowed in third part of the Annex (production of flavours from natural aromatics) with residues restricted to 1 mg/kg and which has replaced n-hexane in analytical laboratory for its lesser toxicity. Iso-hexane, represented here by 2-methyl-pentane, doesn’t match the legal definition of hexane because it boils at 60 °C, but it has also been cited in some studies as a possible substitute for n-hexane; (Johnson and Lusas, 1983), and was therefore included in this comparison. 2-methyloxolane was recently added to the Annex part 2 of the Directive 2009/32 by the Directive 2023/175 of 23 January 2023, for the same use and the same final residues limits as hexane.

Methyl acetate, diethyl ether, butanol, 1-propanol and 1,1,1,2-tetrafluoroethane also listed in the directive’s annex were not considered. Methyl acetate was excluded because its properties are close to those of EA but with a higher water miscibility and higher hazard in terms of flammability (flash point −10 °C versus −4.4 °C, partial pressure at 20 °C: 0.22 atm versus 0.10 atm). Diethyl ether has a boiling point of 34.6 °C which makes it highly volatile and would necessitate refrigeration in extraction sites to operate in safe conditions which would require retrofitting costs that are likely to be too high. 1-butanol, 2-butanol, and 1-propanol have boiling points of 117 °C, 99.5 °C and 97 °C respectively, which are too high in regard of the necessity to preserve the protein feed value since their removal at the desolventization stage would expose the meals to temperatures above these levels to ensure complete desolventization. Tetrafluoroethane being a gas at ambient temperature, it couldn’t replace hexane in existing plants.

Table 1 recapitulates the main physical characteristics of the solvent of the comparison. Hexane is the object of three distinct columns since it is available in several isomers which differ around their boiling point. Nevertheless, the most common quality in use is a technical mixture of isomers containing about 50% of n-hexane, the composition of which varies from one supplier to another. The CAS number 64742-49-0 covers technical hexane and petroleum ether which is poorly defined in terms of composition and englobes mixtures having boiling points ranging from 40 to more than 100 °C. The exact properties of the mixtures in use in the industry is likely to vary accordingly to its composition, therefore, we thought it simpler and more reliable to give the properties of varieties with a better-defined chemical composition.

Collection of physical properties of the solvents and cost indications.

2 Molecules structures, chemical stability, method of production and origin of the raw materials

An ideal solvent should not react with the substances it is intended to extract, nor with the compounds of the solid matrix. It should also not decompose during distillation or desolventization operations, including in the presence of catalysts such as enzymes present in seeds or iron oxides that may form in the equipment. Moreover, its constituent functional groups will define the interactions it will establish with all the substances to which it will be exposed, impacting both its capacity to dissolve oils to varying degrees, to traverse the barriers constituted by cell walls, and to bind to the non-lipidic substrate after extraction. The ideal solvent must also be readily available at reasonable costs. This chapter addresses the question of the chemical nature of solvents, their origin, and indicates global production levels.

Hexanes are alkanes, i.e. saturated hydrocarbons which are produced from petroleum and condensates from natural gas. Normal-hexane and iso-hexanes are produced by fractional distillation and cyclohexane is produced by catalytic hydrogenation of benzene which is a common by-product of catalytic reforming (a technique aiming at increasing the octane index of naphtha). The variety used for the vegetable oil extraction is purified to remove any possible toxic residues like aromatic hydrocarbons (Johnson, 1997). Several suppliers are petroleum refineries operating on the European territory, but non-EU refiners are also supplying the EU crushing industry. Vegetable oil extraction is the largest market for hexane according the ChemAnalyst website (about 40–50%). The global market would represent 1.3 Mt/year in 2022. By order of importance, other uses are: adhesives and sealants, paints and coatings, industrial solvents and others. Cyclo-hexane represent a larger market with 8 Mt in 2022 according to ChemAnalyst which mains use are in textiles, paints and coating, construction and automotive. The price of n-hexane is cheaper than cyclohexane which is a component of its attractiveness.

The chemical stability of alkanes is high because the carbon-hydrogen bond is difficult to break. Oxidation is the most common possible reaction that requires a relatively high energy of activation translated by the autoignition temperature. In absence of functional group alkanes are not likely to react with the substances contained in oil-containing materials (Loudon, 1995).

Alcohols: methanol, ethanol and isopropanol are characterised by a hydroxy function (OH). The specificities of this group are determined by the oxygen atom. It is nucleophilic because of unshared pair of electrons making it prone to attack electrophiles. It is also polarised because of the high oxygen electronegativity and correlative hydrogen positivity. This reactivity is stronger for primary alcohols (methanol and ethanol) and lower for secondary alcohols (IPA) due to increased stabilization by the inductive effect of larger alkane residues. This reactivity can lead to chemical reactions in presence of catalysts like lipases which can generate transesterification between triacylglycerols and alcohols. The polarity brought by the OH group strongly influences the solvent properties of the alcohols, limiting the oil solubility and making them miscible with water.

Methanol is produced by catalytic reformation of syngas, a mixture of carbon monoxide and hydrogen (H2). Syngas is produced from natural gas or by coal or biomass gasification (Ott et al., 2012). The worldwide production reaches 111 Mt/year according to Statista, 90 Mt/year according to the ChemAnalyst, making this substance one of the most produced worldwide. It is used as raw material for the production of formaldehyde, olefins (dimethyl-ether, ethylene, propylene, etc.), benzoline blending (to increase the oxygen in fuels for improving the combustion in engines) or in the synthesis of MTBE (methyl-tert-butyl-ether) and others uses. At 662 $/t, it is the cheapest solvent of the comparison.

Ethanol comes from the fermentation of sugars (cane, beet, or hydrolysed starches from corn or wheat). Worldwide production would reach about 29.5 billion gallons according to Statista (∼88 Mt/year), the USA and Brazil being the top producers with 52 and 28% of the global production. The ChemAnalyst assesses the global production at 102 Mt in 2022. Its main use is in fuels and fuel additives followed by food and beverages, chemistry, cosmetics and personal care products. With 741 $/t, ethanol is attractive by comparison with most of the solvent in this comparison.

Isopropanol is synthesised from propylene (a petroleum refinery derivate) by hydration. The most common route is indirect hydration. The first step is a reaction with sulfuric acid, resulting in isopropyl sulphates, the sulphates are then hydrolysed. A direct route is also possible, but it requires high pressure and high temperature (200–300 ATM, 200–300 °C) (Logsdon and Loke, 2000). The worldwide production of IPA represents 2.3 Mt in 2022 for Statista and 3.1 Mt for the ChemAnalyst. Its main uses are in pharmaceuticals, cosmetics and personal care, chemical and paints and coatings. Compared to other alcohols, IPA is relatively expensive (1499 $/t). It costs more than n-hexane but less than cyclo-hexane, MEK and 2-MeOx.

Ketones: the ketone group is considered stable in the usual conditions of extraction. It confers a lower polarity to the solvent by comparison with the hydroxy group which is an advantage for dissolving lipids. On the other hand, it confers some miscibility with water to the solvent.

Acetone is produced by two major methods. 1) the cumene process: This is the primary method used in large-scale production. It involves the alkylation of benzene with propylene to produce cumene, which is then oxidised to form acetone and phenol as co-products. 2) Isopropyl alcohol dehydrogenation: This method involves the catalytic dehydrogenation of isopropyl alcohol (isopropanol) to form acetone. Its market volume would be 7.1 Mt according to Statista in 2022, 8.8 Mt for the ChemAnalyst. Its main use is as a solvent followed by a basis for methyl-methacrylate, a basis for bisphenol A. The price for acetone (1250 $/t) is between n-hexane and cyclo-hexane, more expensive than for ethanol but similar to ethyl acetate.

MEK can be produced in several routes, dehydrogenation of 2-butanol (most common industrial process), oxidation of n-butene or direct oxidation of n-butane (Weissermel and Arpe, 2008). In most cases, substrates are sourced from petrochemicals. The production volume is 560 kt in 2022 for Statista. MEK is a relatively expensive solvent (1536 $/t), ranking third after 2-MeOx and cyclo-hexane.

Ethyl acetate is an ester formed from acetic acid and ethanol, both molecules that can be sourced from biomass. Its production can also be based on petrol sourced molecules. The ester function is stable in the conditions of use in the extraction industry, but esterase enzymes are potentially present in the oilseeds. However, lipases which are the main esterase in question are specific and not likely to be effective with ethyl acetate. There is no available data about this possible solvent degradation in extraction situations. The global production of ethyl acetate is about 4.8 Mt in 2022 according to the Chem Analyst. The main uses are in paints and coatings, printing inks, and others. Its cost (1281 $/t) is similar to acetone, i.e. more expensive than n-hexane but comparatively more attractive than 2-MeOx with which he has numerous similarities.

Dichloromethane or methylene chloride is a halogenated hydrocarbon. Its structure gives a weak polarity to the molecule and a strong stability making it much less flammable than hexane and other alkanes. In the past, trichloroethylene has been used as extraction solvent because it was considered safer than naphtha but it was discovered that cattle fed with meals containing solvents residues were victims of the “bloody nose disease” or haemorrhagic aplastic anaemia. Since this disease was caused by the solvent residues, the solvent stopped to be used around 1952 (Johnson, 1997). Dichloromethane is listed in Directive 2009/32/EC because of its use for the removal of caffeine, irritants or bittering agents in coffee and tea. It is produced by chlorination of methane or methanol. The first substrate is preferred due to lower costs and higher yields. According to the Chem Analyst, 1.9 Mt were produced in 2022 for pharmaceuticals, agrochemicals, paints and varnishes removers, foam manufacturing and other uses.

DCM is a relatively cheap solvent (695 $/t), that could make it an attractive alternative to hexane if we could disregard the toxicity issues for both humans and the environment.

2-Methyloxolane is an ether with a 5-membered saturated cycle containing four carbon and one oxygen. A methyl group is attached to a carbon adjacent to the oxygen. This cyclic ether structure makes 2-MeOx an effective solvent for various organic compounds. Like other ethers, it is likely to form peroxides during storage because of its cyclic structure. These peroxides are crystallising and are forming shock sensitive explosive crystals during their storage. This risk can be prevented by the addition of food grade antioxidants to the solvent. 2-MeOx is the result of the hydrogenation of furfural, a derivative of pentoses obtained after acid hydrolysis of hemicelluloses followed by a dehydration. Biomasses like cane bagasse or corn cobs are the sources from which furfural can be produced. The market size for this solvent is much lower than for the previous ones and no global statistics on production are available on the production. Several market studies are disclosing estimates of the market values which range from 440 M$ to 3377 M$ for the year 2021 with a median between 489 and 641M$. With a hypothetical market price of about 10 $/kg, the order of magnitude of the production is about 50 to 100 kt/year. Its cost, which Rapinel et al. (2020) place in the range of 7–9 €/kg, is probably the most significant drawback of this solvent.

3 Comparison of physical properties

3.1 Volatility and related properties

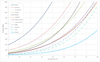

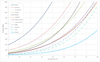

The solvents were selected based on a specific volatility range, ensuring compatibility with liquid-state use at atmospheric pressure. Their boiling points allow evaporation at temperatures that preserve oil and protein quality, while remaining high enough to enable liquefaction using simple cooling systems operating near ambient temperatures. Volatility is represented by the boiling point of the solvents and their vapour pressure. Figure 1 presents the vapour pressure of selected solvents in function of temperature and includes a comparison with water. DCM with boiling point at 40 °C is the most volatile compound followed by acetone (56 °C).

Volatility depends on the molecular mass and the intermolecular bonds which exist between the solvent molecules. Within hexanes, the volatilities vary strongly with 2-methyl-pentane showing a rather high volatility even at low temperatures, n-hexane an intermediate one and cyclohexane a rather low one practically indistinguishable from MEK and ethyl acetate. Its ring structure enhances intermolecular interactions and requires more heat for disruption. This structure is also facilitating its crystallisation leading to a melting point of 7 °C. This characteristic is a drawback for oil mills located in cold places. On the other hand, the high volatility of iso-hexane is a disadvantage in regard of the necessity to limit the solvent losses, since it increases the rate of evaporation in areas communicating with the atmosphere (leaks). Methanol presents the highest volatility among alcohols due to its low molecular mass. Its curve resembles the one of n-hexane but with a lower pressure at low temperature and a higher one at high temperature. This kinetic could be an advantage because it limits the evaporation at ambient temperature and reduces the boiling point, but as it will be discussed later, this is strongly countered by its much higher latent heat of vaporisation. Ethanol and IPA are the less volatile solvents. Like methanol, their vapour pressure at ambient temperature are low. On the contrary, acetone is much more volatile than the n-hexane and it presents relatively high vapour pressure at room temperature.

Flash point (FP) is the lowest temperature at which a solvent can vaporize to form an ignitable mixture with air. At this temperature, the solvent produces enough vapor to momentarily ignite when exposed to an ignition source, but the flame may not be sustained. Determining flash point is not trivial. It requires significant expertise to observe the tiny, momentary flame. Consequently, results can vary between different sources and testing methods. Hexanes exhibit the lowest flash point and according to the Antoine equation, the lower partial pressure at FP temperature (14 mbar). At the other extremity of the spectrum, methanol has the highest FP (16 °C) and the highest partial pressure at FP temperature (103 mbar). So, FP is not the simple reflect of the volatility of the solvents, but it measures also its reactivity with oxygen. The flammability of alcohols strongly correlates with their carbon number: ethanol, FP 13 °C (38 mbar); isopropanol, FP 12 °C (26 mbar). A similar trend is observed in ketones: acetone, FP −9.4 °C (56 mbar); methyl ethyl ketone, FP −5.6 °C (22 mbar). 2-Methyloxolane is slightly more flammable than ethyl acetate with respectively: FP −10 °C (20 mbar) and FP −4.4 °C (25 mbar).

Further analysis of these parameters in relation to flammability is supplied in the second section of this study concerning the hazards control.

|

Fig. 1 Partial pressure of the solvents vapours in function of the temperature calculated from the Antoine equation parameters. Sources NIST (2024) database, except for 2-MeOx calculation from Tables TRC (1974). |

3.2 Emissions thresholds (VOCs)

Volatility is also an issue related to solvent emission into the environment. As defined by EU “Volatile organic compound: any organic compound emanating from human activities, other than methane, which can produce photochemical oxidants by reacting with nitrogen oxide in the presence of sunlight, having a vapour pressure above 10 Pa at 293.15 K (20 °C)”. They contribute to the formation of tropospheric ozone (which is both a hazardous air pollutant and a greenhouse gas). Therefore, the solvents are categorised by their ease to evaporate (boiling point). They are classified in three classes according to WHO (1982) based on the substance boiling point (very volatile OC: 0–50 °C; volatile OC: 50–240 °C; semi-volatile OC: 240–400 °C). The initial Directive 1999/13/EC (Council, 1999) for volatile organic compounds (VOCs) has been replaced by the Directive 2010/75/EU. It specifies that crushing units using more than 10 t of solvent per year must limit their emissions of VOCs to 1 kg per metric ton of rapeseed and sunflower, 0.8 kg/t of soybean (regular crushing) or 1.2 kg/t in the case of white-flakes. Castor benefits from a higher tolerance up to 3 kg/t of seeds. This regulation has been transposed in each country legislation which could be more restrictive. For example, in France the emissions limits are determined for each oil mill by the local authorities as part of the authorisation dossier, which specifies the various parameters that the facility must respect in terms of its impact on the environment.

In the USA, acetone was removed from the VOC’s on the basis of its negligible photochemical reactivity (Hron, 1997).

BREFs are comprehensive documents that describe the Best Available Techniques (BAT) for a given industrial sector. They are the result of an information exchange process known as the Sevilla process, involving EU Member States, industries, environmental NGOs, and the European Commission. In the case of the oil mill industry, this work is included in the document concerning all the food, milk and beverages industry. The specificities for this branch were detailed in chapter 11 (Santonja et al., 2019). According to this document, the predominant sources of emissions are the meals (0.05–0.3 kg of solvent/t) and fugitive losses including losses occurring in start-ups and shutdowns (0.1–0.5 kg/t). The third source of losses by importance is the exhaust of the mineral oil scrubber (0.05–0.15 kg/t), while the losses in crude oil are low (0.02–0.05 kg/t). The document presents a figure (fig. 11–15) in which the specific hexane consumption is given for 27 units crushing rapeseed and soybean across the EU. The emissions range from 0.2 to 0.82 kg/t with only seven units above 0.7 kg/t. From this document, an official Decision of the European Commission (EU/2019/2031 of 12 November 2019) has been adopted in which the techniques for limiting the emissions of hexane are specified (use of counterflow steam in the desolventizer, evaporation of the miscella using the vapours from the desolventizer-toaster (DT), use of condensers to recover the solvent combined with a mineral oil scrubber to absorb the uncondensed vapours, and passage of wastewater in a boiler to evaporate the hexane residues). Solvent loss limits are specified by seed type: for rapeseed and sunflower, up to 0.7 kg of solvent per ton of crushed seeds; for soybean: up to 0.55 kg of hexane per ton of seeds.

To ensure fair trading practices, Regulation 68/2013 on the Catalogue of feed materials establishes a limit of 0.1% for processing aids present in feed materials. This limit is above the usual residue levels described in the BREF, 0.05–0.3 kg of solvent/t of seed i.e. roughly the equivalent in quantity to ∼ 90–540 mg/kg of meal.

4 Solvents and extraction technology

After examining the chemical stability of solvents and their availability, their volatility, and certain flammability characteristics, we will now focus on the crucial question of interactions between solvents and solutes, that is, the capacity of solvents to effectively dissolve oils, penetrate cell walls, and selectively extract molecules.

4.1 The basics of solvent extraction

Solvent extraction is a method which is based on the principle of the Fick’s law of diffusion. This law of diffusion states that substances move from areas of high concentration to areas of low concentration at a rate proportional to the concentration gradient. In the context of oilseed extraction, when seeds are soaked in solvent, oil diffuses from the oil-rich solid material into the initially oil-poor liquid solvent phase. The diffusion of the oil in the solvent is faster for the oil which is at the surface of the particles or included in the superficial layers and it requires more time for the oil which is included in intact cells at the core of the particles. The degree of milling, i.e. the particle size and the percentage of disrupted cell walls, is an important factor regarding the speed of oil diffusion in the solvent. Once the concentrations are at equilibrium, it is possible to remove the liquid phase (the miscella) and to evaporate the solvent to recover the oil it contains. Since the solid-liquid separation is generally made by drainage, some liquid is kept in the solid (the marc) and this liquid has the same oil concentration as the recovered miscella. To recover this residual oil and to decrease the concentration of undissolved oil in the solid, the marc is washed with new solvent. The number of washes required to exhaust the solid depends on the volume of solvent employed for each extraction step, and of the duration of each step. To save time, industrial operators generally do not wait until reaching equilibrium before starting a new step at a lower concentration because when concentration differential weakens, the diffusion slows down. In the oil mill industry counterflow extractor are employed to minimise the volume of solvent required (Anderson, 2024). The principle of counterflow consists in contacting almost exhausted marc with fresh solvent to remove the last residues of oil and then using the weakly concentrated miscella to extract the marc upstream with higher oil content and repeating the operation for six to ten steps. The final miscella reaches high oil concentration and the ratio between solvent and solid can be reduced in a range of 1.0 up to 1.5 times the mass of extracted material. At the outlet of the extractor, the exhausted marc is sent in a desolventizer-toaster (DT) where it is heated in presence of sparge steam to recover the solvent and strip the meal of residues. The miscella is evaporated and its residues in the oil are stripped using a combination of vacuum, heat, and steam injection.

4.2 Solubility of oils in the solvent

Solubility requires that the solvent and the oil share several characteristics which could be globally expressed as a marked hydrophobicity. This criterion is often measured by the logPo/w (also known as log Ko/w) a dimensionless number which is the decimal logarithm of the ratio between the substance concentration in each fraction of an n-octanol/water system. For example, if the concentration in octanol is 10 times greater than in water the logPO/W of the substance is 1 and −1 if the concentration is 10 times greater in water than in octanol. Negative values for methanol, ethanol and acetone are indicators that these solvents do not have a great affinity for the lipids and the relatively low positive values of IPA and MEK are showing that although they prefer the lipids to the water, a significant part of them remains in the aqueous phase. On this point of view, ethyl acetate is more hydrophobic but only 2-MeOx presents a logPO/W above 1 among “green” alternative solvents to hexane. This approach is not sufficient to characterise the solvent properties but as an indicator of hydrophobicity, logPo/w gives us an interesting first ranking. It is closely related to the water miscibility in the solvent and reciprocally, the solvent miscibility in water, the negative values methanol and ethanol and the weak one of acetone and IPA are well correlated to the total miscibility of the substances with water. Then logically, the higher the logP for the other solvent the lower their water miscibility. The dipole moment measured in Debye units results from the electronegativity of the oxygen atom in the molecules which generates a differential in electron density in the molecule. Alkanes having no oxygen atom exhibit very low dipole moments. The strongest dipole moments are found in methanol, MEK and acetone. These have a relatively high logP, meaning the correlation between, logP and dipole moments is loose and cannot predict the dipole moment of solvents like ethanol and acetone. Dipole moment relates to the polarity of the solvents and predicts their ability to stabilise charged polar species while hydrophobicity results from multiple intermolecular interactions. The dielectric constant is another measure of the polarity of the solvents considered as the ability to separate electrically charged particles or highly polar groups. Through this measure, ethanol and acetone look more similar than through dipole moments. The regression between LogP and dielectric constant is a non-linear curve from which ethyl acetate deviates. In result, polarity and hydrophobicity alone cannot predict with accuracy the solvent behaviour in regard to the lipids and other tools are required to assess their potential efficiency.

Solvents can be classified based on their polarity, protic nature, and donor properties, which significantly influence their ability to extract various compounds from plant matrices (Reichardt and Welton, 2011). Polar solvents, characterized by high dielectric constants, effectively dissolve polar molecules and ions. Protic solvents, containing labile hydrogen atoms, can form hydrogen bonds and donate protons, while aprotic solvents lack this ability (Reichardt, 2003). Donor solvents can act as Lewis bases, donating electron pairs in chemical reactions (Laurence and Gal, 2009). Apolar and donor solvents like EA and 2-MeOx can interact with a wider range of lipids than apolar non donor solvents like hexanes. This classification is also crucial in lipid extraction from vegetable matrices, as it determines the solvent’s capacity to disrupt cell membranes and solubilize different lipid classes (Iverson et al., 2001). For instance, a combination of polar and non-polar solvents is often used to extract both neutral and polar lipids effectively (Folch et al., 1957; Bligh and Dyer, 1959). Moreover, this classification is relevant for the extraction of non-lipid substances of interest to the oil mill industry, such as chlorophylls, polyphenols, and pesticides. Polar protic solvents like alcohols can effectively extract polyphenols (Dai and Mumper, 2010), while chlorophylls are more soluble in non-polar or slightly polar solvents (Lichtenthaler, 1987). Most insecticides used in grain storage (pyrethroids, organochlorides, organophosphorous) are strongly hydrophobic and can be extracted in the oils during processing (Anastassiades et al., 2003). Ionic substances like glucosinolates, important antinutritional factors in rapeseed, dissolve poorly in most organic solvents of interest for oil extraction but present some solubility in methanol.

The most common way of measuring the affinity between a solvent and a substance is the Hansen relative energy difference criterion (RED) which is the ratio between Ra/R0, where Ra is the relative distance between the three Hansen solubility parameters of the solvent and the solute (Eq. (1)), and R0, a characteristic of the solute which is experimentally determined and corresponds to the radius of solubility. The Hansen Solubility Parameters (HSP) measure the intermolecular bonding according to the non-polar interactions (atomic dispersion) δD, molecular dipole interactions δP, and hydrogen bonding δH. The SI units for these parameters are in MPa1/2 (Hansen, 2000).

Table 2 gives some available figures on the Hansen solubility parameters of some vegetable oils and our solvents. The RED values for palm oil are those found in Batista et al. (2015) for palm oil and in Sicaire et al. (2015) in the case of 2-MeOx for average value of four triacylglycerols representative of major vegetable oils.

Normal hexane, with low molecular dipole interactions δP, and hydrogen bonding δH has not the lowest RED among the solvents. DCM, MEK, EA, cyclo-hexane and 2-MeOx are characterised by better affinity for triacylglycerols. In addition, Table 3 shows the Ra distances (Eq. (1)) between the plant oils and the solvents for which R0 values are not available. This table shows that 2-MeOx, hexanes and EA are the solvents that have the smallest Ra distances for the vegetable oils while alcohols, especially methanol, exhibit the poorest compatibility. Ketones and DCM have slightly lower miscibility in vegetable oils than the best solvents, but are still suitable for extraction, although acetone exhibits a lesser suitability than MEK and DCM.

A strict equivalence between the RED value in Table 2 for palm oil and the Ra values in Table 3 for the same oil cannot be established when compared, but the essential ranking is nevertheless maintained.

The affinity of the solvents for the oils is only an aspect of their efficiency. With no time limit and large ratios of solvent to oilseed, except methanol, any solvent of our short list is able to exhaust the oil-containing material. What is wanted is a fast total extraction. In this light, non-polar solvents like hexane may be handicapped because their hydrophobicity limits their ability to cross the cell walls. Several studies have observed better oil yields using alternative solvents. Seth et al. (2007) comparing IPA and hexane found that with non-flaked soybean IPA was able to overcome the reduced accessibility to oil allowing a 96% rate versus 79% with hexane. Proctor and Bowen (1996) making similar comparisons on rice bran did not see differences between the solvents, but rice bran had small particle sizes (<100 μm). Lohani et al. (2015) made a comparison between EA and hexane on canola, camelina, flax and mustard using a pressurised lab extractor (∼100 bar). For canola and mustard, hexane led to slightly better oil yields (2 and 3% on average) while with flaxseed and camelina EA gave better results (+7 and +14%, respectively) probably because these seeds were harder to ground and giving the advantage to EA for the capacity to cross cell walls. De Oliveira et al. (2013) compared acetone, IPA and EtOH to hexane for the extraction of passion fruit seeds. In a Soxhlet apparatus, hexane oil yields were far better than yields of alternative solvents (15.1, 14.0, 15.9 versus 26.4% for respectively acetone, EtOH, IPA and hexane). This result is rather surprising since extraction time was not limiting and after 8 hours of extraction, yields were not improving. Sicaire et al. (2015) compared hexane and 2-MeOx on pre-pressed rapeseed. The final oil yields were similar but with 2-MeOx the extraction kinetic was faster. Saxena et al. (2011) have compared EtOH and hexane efficiency on cotton seeds. At low temperatures (35 °C) and solvent to solid ratio 5:1, hexane obtained almost 30% more oil on small particles. At 45 °C, with a solvent to solid ratio 10:1, EtOH had a greater efficiency than hexane reaching 90% yields in less than 60 minutes, while hexane required about 150 minutes for the same yield. In an unpublished study comparing hexane with ethanol and IPA on pre-pressed rapeseed using a pilot percolation extractor with solvent to solid ratios of 2.5:1 and extraction times of 10 minutes at temperatures 10 °C below the boiling of the solvents, we observed similar oil yields but an advantage for hexane for the number of washes required to exhaust the press cake. Only six operations were required for hexane versus eight for both alcohols.

It can be concluded from this review that hexane performs better with materials where oil access is relatively easy, such as when cell walls have been thoroughly disrupted and when the material’s porosity or particle size has minimized the distance the solvent must traverse. This advantage results in high selectivity for neutral lipids and facilitates purification steps. However, donor and apolar solvents like ethyl acetate (EA) and 2-methyltetrahydrofuran (2-MeTHF) enhance the solvent’s ability to diffuse across matrices and improve lipid extraction capacity without significantly compromising oil purity. These solvents could tolerate less intensive preparation and facilitate the operation oil mills.

Hansen solubility parameters for vegetables oils (MPa1/2).

HSP Ra distance between vegetable oils and solvents Hansen solubility parameters.

HSP Ra distances between some lipids and non-lipid compounds and the solvents.

4.3 Specificity/selectivity

Another desirable character is the selectivity of the solvent. A good solvent will extract only lipids and leave non-lipid material in the spent cake. Among undesirable compounds, one can cite soluble sugars, phenolic compounds, pesticides, mycotoxins, allergens, etc. The case of polar lipids, especially phospholipids is ambivalent since as source of phosphorus, these compounds are not wanted in edible oils, but they can be recovered and marketed after drying as lecithin. Indeed, as the market for lecithin is not able to use all of the potential lecithin production, many oil mills do not recover the phospholipids after the water degumming step and the wet gums are reincorporated in the meals. Since degumming can lead to some losses in neutral oil, a better extraction yield of polar lipids is not always desired.

Table 4 gives the Ra distances of some lipids and non-lipids compounds with our solvent selection. Diglycerides have excellent solubility in 2-MeOx and EA, good solubility in hexanes and DCM, fair solubility in ketones and poor solubility in alcohols with a gradation according to the carbon number. Monoglycerides are more polar than DAG and dissolve better in ketones than in hexanes. Their best solvent is EA followed by DCM and 2-MeOx. IPA also performs better than hexanes and only EtOH and MeOH are ranking below these alkanes. For tocopherols and phytosterols which are much less polar, the ranking is 2-MeOx ∼ Cyc.H > n-H. > EA ∼ iso.H. ∼ DCM > MEK > acetone > IPA > EtOH > MeOH. Phosphatidylcholine which is considered as a polar lipid prefers solvents with intermediate δP, and δH as EA, DCM and 2-MeOx. MEK and acetone are theoretically miscible although it is known that phospholipids (PL) are not soluble in acetone.

The failure of Hansen Solubility Parameters to accurately predict the insolubility of phospholipids in acetone can be attributed to several factors related to the complexity of phospholipid structures and the limitations of the HSP model. Phospholipids have a unique amphiphilic structure, consisting of both hydrophilic (polar head group) and hydrophobic (fatty acid tails) regions. This complexity is not fully captured by the three Hansen parameters (Coutinho et al., 2022). The HSP model reduces molecular interactions to three parameters (δD, δP, δH), which may not adequately represent the complex interactions in phospholipid systems. The HSP model assumes that molecules interact uniformly, which is not the case for phospholipids with distinct polar and non-polar regions. Furthermore, HSP does not account for specific molecular interactions like ion-dipole forces or the ability of phospholipids to form bilayers or micelles in solution. Acetone is a polar aprotic solvent with moderate hydrogen bonding ability. While it can interact with the polar head groups of phospholipids, it cannot effectively solvate the entire molecule. The presence of water molecules (even in small amounts) can enhance the aggregation of phospholipids, further reducing their solubility in acetone (Nasrollahi et al., 2020). The insolubility of phospholipids in acetone is actually exploited in lipid fractionation techniques. Acetone precipitation is commonly used to separate polar lipids (phospholipids and glycolipids) from neutral lipids.

Hexanes are not performant solvents for the PL with Ra distances above 10, but in reality, it is possible to extract the PL during hexane extraction. It takes more time than with neutral lipids and the extraction yield is generally lower. In experimental solvent comparisons, its often observed that more lipids can be extracted with more polar solvents

The experimental comparison of solvents on oil yields will be found in the third article of this series (Processing) and the comparisons about the oil composition will be found in the part five (oil quality).

5 Conclusion

This comprehensive analysis of potential hexane alternatives for edible oil extraction reveals a diverse range of solvents with varying physical and chemical properties. The most critical characteristics for consideration include boiling point, vapour pressure, flash point, miscibility with water, and affinity for lipids. Hexane and its isomers remain the benchmark, offering high affinity for non-polar lipids and low boiling points. However, regulatory pressures necessitate the exploration of alternatives. Alcohols like ethanol and isopropanol present interesting possibilities, with ethanol’s weak affinity for lipids potentially advantageous when using temperature as a miscibility modifier. By cooling the miscella, it may be possible to avoid distillation, offering energy savings in the extraction process; this point will be developed in the next sections about processing and energy. Ketones such as acetone and MEK offer a balance between polarity and non-polarity, showing potentially good affinity for both polar and non-polar lipids and some similarities with alcohols for the non-distillation recovery of oil. Their specificity is their poor capacity to dissolve phospholipids which could be an advantage for avoiding the water degumming step. Ethyl acetate demonstrates promising solvent power across various lipid types, while 2-methyloxolane efficiently extracts both polar and non-polar lipids appears to be the solvent most similar to hexane in its Hansen solubility parameters. Dichloromethane (DCM) could be an intriguing option if toxicity concerns were set aside, given its high affinity for lipids and non-flammability. However, its use remains limited due to safety considerations. It is important to note that methanol, despite being included in the comparison, is not a viable competitor due to its poor miscibility with oils. This limitation, along with other factors, will be further elaborated in subsequent parts of the article, confirming its unsuitability for oil extraction. The choice of an alternative solvent will ultimately depend on a balance of factors including extraction efficiency, energy requirements, safety considerations, and regulatory compliance. Temperature modulation, as mentioned with ethanol, could play a crucial role in optimising the extraction process for certain solvents. As the industry moves forward, it will be essential to consider not only the physical properties of these solvents but also their impact on oil quality, protein preservation in meals, and overall process economics. The ideal replacement for hexane may vary depending on specific applications and regional regulations, necessitating a flexible approach to solvent selection in the edible oil industry.

Conflicts of interest

The authors have no conflicts of interest to disclose.

Author contribution statement

Patrick Carré: conceptualization, administration, original draft, review & editing. Sebastian Berthold: conceptualization, administration. Thomas Piofczyk: conceptualization, validation, review & editing. Sarah Bothe: validation, review & editing. Sara Hadjiali: validation, review & editing.

References

- Anastassiades M, Lehotay SJ, Štajnbaher D, Schenck FJ. 2003. Fast and easy multiresidue method employing acetonitrile extraction/partitioning and “dispersive solid-phase extraction” for the determination of pesticide residues in produce. J AOAC Int 86: 412–431. [CrossRef] [PubMed] [Google Scholar]

- Anderson J. 2024. Solvent extraction. Lipid Library − American Oil Chemists’ Society. Retrieved October 12, 2024, from https://lipidlibrary.aocs.org/edible-oil-processing/solvent-extraction [Google Scholar]

- Batista MM, Guirardello R, Krähenbühl MA. 2015. Determination of the Hansen solubility parameters of vegetable oils, biodiesel, diesel, and biodiesel-diesel blends. J Am Oil Chem Soc 92: 95–109. [CrossRef] [Google Scholar]

- Bligh EG, Dyer WJ. 1959. A rapid method of total lipid extraction and purification. Can J Biochem Physiol 37: 911–917. [CrossRef] [PubMed] [Google Scholar]

- ChemAnalyst. 2024. https://www.chemanalyst.com/Pricing/Pricingoverview. Last consult July 2024 [Google Scholar]

- Commission Implementing Decision (EU) 2019/2031 of 12 November 2019 establishing best available techniques (BAT) conclusions for the food, drink and milk industries, under Directive 2010/75/EU of the European Parliament and of the Council (notified under document C (2019) 7989). Official Journal of the European Union L 313, 4.12.2019, p. 60–93 [Google Scholar]

- Council Directive 1999 /13/EC of 11 March 1999 on the limitation of emissions of volatile organic compounds due to the use of organic solvents in certain activities and installations. Official Journal of the European Communities L 85, 29.3.1999, p. 1–22. [Google Scholar]

- Coutinho JAP, Martins MAR, Fernandes AM. 2022. Using COSMO-RS to predict hansen solubility parameters. Ind Eng Chem Res 61: 9729–9738. [Google Scholar]

- Dai J, Mumper RJ. 2010. Plant phenolics: extraction, analysis and their antioxidant and anticancer properties. Molecules 15: 7313–7352. [CrossRef] [PubMed] [Google Scholar]

- De La Peña-Gil A, Toro-Vazquez JF, Rogers MA. 2016. Simplifying Hansen solubility parameters for complex edible fats and oils. Food Biophys 11: 283–291. [CrossRef] [Google Scholar]

- De Oliveira RC, De Barros STD, Gimenes ML. 2013. The extraction of passion fruit oil with green solvents. J Food Eng 117: 458–463. [CrossRef] [Google Scholar]

- Directive 2010/75/EU of the European Parliament and of the Council of 24 November 2010 on industrial emissions (integrated pollution prevention and control) (recast). Official Journal of the European Union L 334, 17.12.2010, p. 17–119. [Google Scholar]

- European Commission. 2023, January 26. Commission Directive (EU) 2023/175 of 26 January 2023 amending Directive 2009/32/EC of the European Parliament and of the Council as regards 2-methyloxolane. Official Journal of the European Union L 25, 67–69. [Google Scholar]

- European Parliament and Council of the Europa Union. 2009. Directive 2009/32/EC of the European Parliament and of the Council of 23 April 2009 on the approximation of the laws of the Member States on extraction solvents used in the production of foodstuffs and food ingredients. Official Journal of the European Union L 141, 3–11. [Google Scholar]

- Folch J, Lees M, Sloane Stanley GH. 1957. A simple method for the isolation and purification of total lipides from animal tissues. J Biol Chem 226: 497–509. [CrossRef] [PubMed] [Google Scholar]

- Gregory S, Horseman M. 2004. Who need alternative solvent, and criteria for their selection, in Wan PJ, & Wakelyn PJ (Eds.). Technology and solvents for extracting oilseeds and nonpetroleum oils. The American Oil Chemists Society pp 1–3. [Google Scholar]

- Hansen, 2024. www.hansen-solubility.com/HSP-examples/cleaning.php. Last consult July 2024. [Google Scholar]

- Hansen CM. 2000. Hansen solubility parameters. A user’s handbook. CRC Press. [Google Scholar]

- Hernández E, Díaz M, Pérez K. 2021. Determination of Hansen solubility parameters for sugarcane oil. Use of ethanol in sugarcane wax refining. Grasas y Aceites 72: e408–e408. [CrossRef] [Google Scholar]

- Hron HR. 1997. Acetone, in Wan PJ, Wakelyn PJ (Eds.). Technology and solvents for extracting oilseeds and nonpetroleum oils. The American Oil Chemists Society, pp186–191A. [Google Scholar]

- Huntsman. 1999. Comparative solvents data. Leaflet. The Woodlands TX: Huntsman Corporation. https://www.huntsman.com/docs/Documents/JEFFSOL%20Alkylene%20Carbonates%20Comparative%20Solvents%20Data.pdf. Last consult July 2024 [Google Scholar]

- Huang Z, Sha J, Chang Y, Cao Z, Hu X, Li Y, Ren B, et al., 2021. Solubility measurement, model evaluation and Hansen solubility parameter of ipriflavone in three binary solvents. The Journal of Chemical Thermodynamics 152: 106285. [CrossRef] [Google Scholar]

- Iverson SJ, Lang SL, Cooper MH. 2001. Comparison of the Bligh and Dyer and Folch methods for total lipid determination in a broad range of marine tissue. Lipids 36: 1283–1287. [CrossRef] [PubMed] [Google Scholar]

- Johnson L, Lusas EW. 1983. Comparison of alternative solvents for oils extraction. J Am Oil Chem Soc 60: 229–242. [Google Scholar]

- Johnson LA. 1997. Analyses of alternative solvent technologies in Wan PJ, & Wakelyn PJ (Eds.). Technology and solvents for extracting oilseeds and nonpetroleum oils. The American Oil Chemists Society, pp 4-47. [Google Scholar]

- Laurence C, Gal JF. 2009. Lewis basicity and affinity scales: Data and measurement. John Wiley & Sons. [CrossRef] [Google Scholar]

- Lichtenthaler HK. 1987. Chlorophylls and carotenoids: Pigments of photosynthetic biomembranes. Methods Enzymol 148: 350–382. [CrossRef] [Google Scholar]

- Logsdon JE, Loke RA. 2000. Isopropyl Alcohol. In Kirk-Othmer Encyclopedia of Chemical Technology. John Wiley & Sons Inc. https://doi.org/10.1002/0471238961.0919151612150719.a01 [Google Scholar]

- Lohani UC, Fallahi P, Muthukumarappan K. 2015. Comparison of ethyl acetate with hexane for oil extraction from various oilseeds. J Am Oil Chem Soc 92: 743–754. [CrossRef] [Google Scholar]

- Loudon GM. 1995. Organic Chemistry (3rd ed.). Benjamin/Cummings Publishing Company. p 72. [Google Scholar]

- Nakamura D, Hirano M, Ohta R. 2017. Nontoxic organic solvents identified using an a priori approach with Hansen solubility parameters. Chemical communications 53: 4096–4099. [CrossRef] [PubMed] [Google Scholar]

- Nasrollahi F, Varshosaz J, Khodadadi A, Lim S, Jahanian-Najafabadi A. 2020. Measurement of hansen solubility parameters of human stratum corneum. Adv Pharm Bull 10: 571–578. [Google Scholar]

- NCBI (National Center for Biotechnology Information). 2024. PubChem Compound Database. National Library of Medicine (US), https://pubchem.ncbi.nlm.nih.gov/ (Last consult July 2024) [Google Scholar]

- NIST database. https://webbook.nist.gov/chemistry/name-ser/. Last consult July 2024 [Google Scholar]

- Ott J, Gronemann V, Pontzen F, Fiedler E, Grossmann G, Kersebohm DB, Weiss G, Witte C. 2012. Methanol. In Ullmann’s Encyclopedia of Industrial Chemistry. Wiley-VCH Verlag GmbH & Co. KGaA. https://doi.org/10.1002/14356007.a16_465.pub3 [Google Scholar]

- Proctor A, Bowen DJ. 1996. Ambient-temperature extraction of rice bran oil with hexane and isopropanol. J Am Oil Chem Soc 73: 811–813. [CrossRef] [Google Scholar]

- Rapinel V, Claux O, Abert-Vian M, McAlinden C, Bartier M, Patouillard N, .. &S Chemat F. 2020. 2-methyloxolane (2-MeOx) as sustainable lipophilic solvent to substitute hexane for green extraction of natural products. Properties, applications, and perspectives. Molecules 25: 3417. [Google Scholar]

- Reichardt C. 2003. Solvents and solvent effects in organic chemistry. Wiley-VCH. [Google Scholar]

- Reichardt C, Welton T. 2011. Solvents and solvent effects in organic chemistry. John Wiley & Sons. [Google Scholar]

- Santonja GG, Karlis P, Stubdrup KR, Brinkmann T, Roudier S. 2019. Best Available Techniques (BAT) reference document for the food, drink and milk industries. Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control), 3. [Google Scholar]

- Saxena DK, Sharma SK, Sambi SS. 2011. Comparative extraction of cottonseed oil. ARPN J Eng Appl Sci 6: 84–89. [Google Scholar]

- Seth S, Agrawal YC, Ghosh PK, Jayas DS, Singh BPN. 2007. Oil extraction rates of soya bean using isopropyl alcohol as solvent. Biosyst Eng 97: 209–217. [CrossRef] [Google Scholar]

- Sicaire AG. 2016. Solvants alternatifs et techniques innovantes pour l’éco-extraction des huiles végétales à partir de graines oléagineuses (Doctoral dissertation Université d’Avignon). [Google Scholar]

- Sicaire AG, Vian M, Fine F, Joffre F, Carré P, Tostain S, Chemat F. 2015. Alternative bio-based solvents for extraction of fat and oils: solubility prediction, global yield, extraction kinetics, chemical composition and cost of manufacturing. Int J Molec Sci 16: 8430–8453. [CrossRef] [Google Scholar]

- Smallwood I. 2012. Handbook of organic solvent properties. Butterworth-Heinemann. [Google Scholar]

- Tables TRC. 1974. Selected values of properties of chemical compounds. Thermodynamic Research Center Data Project Texas A&M University College Station, 971: 2605–2609. [Google Scholar]

- Weissermel K, Arpe H-J. 2008. Industrial organic chemistry. John Wiley & Sons. [Google Scholar]

- World Health Organization. 1992. An Introductory guide to human exposure field studies: survey methods and statistical sampling (No. UNEP/GEMS/92. H4. Unpublished). World Health Organization. [Google Scholar]

Cite this article as: Carré P, Berthold S, Piofczyk T, Bothe S, Hadjiali S. 2024. Solvent solutions: comparing extraction methods for edible oils and proteins in a changing regulatory landscape. Part 1: Physical-properties. OCL 31: 31., https://doi.org/10.1051/ocl/2024027

All Tables

HSP Ra distance between vegetable oils and solvents Hansen solubility parameters.

All Figures

|

Fig. 1 Partial pressure of the solvents vapours in function of the temperature calculated from the Antoine equation parameters. Sources NIST (2024) database, except for 2-MeOx calculation from Tables TRC (1974). |

| In the text | |

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.